| 211-05 Steering Wheel and Column Electrical Components

|

2013 - 2014 MKZ

|

| Diagnosis and Testing

|

Procedure revision date:

07/19/2013

|

Steering Wheel and Column Electrical Components

DTC Charts

Chart

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices.

REFER to:

Diagnostic Methods

(100-00 General Information, Description and Operation).

|

|

Description

|

Action

|

|

B108A:01

|

Start Button: General Electrical Failure

|

GO to Pinpoint Test A

|

|

B108A:24

|

Start Button: Signal Stuck high

|

GO to Pinpoint Test A

|

|

B1142:29

|

Ignition Status 1: Signal Invalid

|

GO to Pinpoint Test A

|

|

B1240:11

|

Start Button Mode Indicator: Circuit Short to Ground

|

REFER to:

Instrument Panel Cluster (IPC) and Panel Illumination

(413-00 Instrument Panel Cluster (IPC) and Panel Illumination, Diagnosis and Testing).

|

|

B1240:15

|

Start Button Mode Indicator: Circuit Short to Battery or Open

|

REFER to:

Instrument Panel Cluster (IPC) and Panel Illumination

(413-00 Instrument Panel Cluster (IPC) and Panel Illumination, Diagnosis and Testing).

|

|

B130F:12

|

Run Accessory Control: Circuit Short to Battery

|

REFER to:

Wipers and Washers

(501-16 Wipers and Washers, Diagnosis and Testing).

|

|

B130F:14

|

Run Accessory Control: Circuit Short to Ground or Open

|

REFER to:

Wipers and Washers

(501-16 Wipers and Washers, Diagnosis and Testing).

|

|

B1310:12

|

Run/Start Control: Circuit Short to Battery

|

GO to Pinpoint Test D

|

|

B1310:14

|

Run/Start Control: Circuit Short to Ground or Open

|

GO to Pinpoint Test A

|

|

U0212:87

|

Lost Communication With Steering Column Control Module: Missing Message

|

REFER to:

Body Control Module (BCM)

(419-10 Multifunction Electronic Modules, Diagnosis and Testing).

|

|

U300A:01

|

Ignition Switch: General Electrical Failure

|

DIAGNOSE and REPAIR all other

Diagnostic Trouble Codes (DTCs).

REFER to:

Body Control Module (BCM)

(419-10 Multifunction Electronic Modules, Diagnosis and Testing).

|

|

All other Diagnostic Trouble Codes (DTCs)

|

-

|

REFER to:

Body Control Module (BCM)

(419-10 Multifunction Electronic Modules, Diagnosis and Testing).

|

Chart

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices.

REFER to:

Diagnostic Methods

(100-00 General Information, Description and Operation).

|

|

Description

|

Action

|

|

B1007:09

|

High-Beam Headlamp Switch: Component Failure

|

REFER to:

Headlamps

(417-01 Exterior Lighting, Diagnosis and Testing).

|

|

B1008:09

|

Wiper Mode Switch: Component Failure

|

REFER to:

Wipers and Washers

(501-16 Wipers and Washers, Diagnosis and Testing).

|

|

B1051:09

|

Front Washer Switch: Component Failure

|

REFER to:

Wipers and Washers

(501-16 Wipers and Washers, Diagnosis and Testing).

|

|

B1052:09

|

Rear Washer Switch: Component Failure

|

REFER to:

Wipers and Washers

(501-16 Wipers and Washers, Diagnosis and Testing).

|

|

B10AD:02

|

Rain Sensor: General Signal Failure

|

REFER to:

Wipers and Washers

(501-16 Wipers and Washers, Diagnosis and Testing).

|

|

B10AD:08

|

Rain Sensor: Bus Signal/Message Failure

|

REFER to:

Wipers and Washers

(501-16 Wipers and Washers, Diagnosis and Testing).

|

|

B10AD:49

|

Rain Sensor: Internal Electronic Failure

|

REFER to:

Wipers and Washers

(501-16 Wipers and Washers, Diagnosis and Testing).

|

|

B10AD:55

|

Rain Sensor: Not Configured

|

REFER to:

Wipers and Washers

(501-16 Wipers and Washers, Diagnosis and Testing).

|

|

B1131:02

|

Wiper motor module: General Signal Failure

|

REFER to:

Wipers and Washers

(501-16 Wipers and Washers, Diagnosis and Testing).

|

|

B1131:08

|

Wiper motor module: Bus Signal/Message Failure

|

REFER to:

Wipers and Washers

(501-16 Wipers and Washers, Diagnosis and Testing).

|

|

B1131:11

|

Wiper motor module: Circuit Short To Ground

|

REFER to:

Wipers and Washers

(501-16 Wipers and Washers, Diagnosis and Testing).

|

|

B1131:49

|

Wiper motor module: Internal Electronic Failure

|

REFER to:

Wipers and Washers

(501-16 Wipers and Washers, Diagnosis and Testing).

|

|

B1131:55

|

Wiper motor module: Not Configured

|

REFER to:

Wipers and Washers

(501-16 Wipers and Washers, Diagnosis and Testing).

|

|

B1131:9A

|

Wiper motor module: Component or System Operating Conditions

|

REFER to:

Wipers and Washers

(501-16 Wipers and Washers, Diagnosis and Testing).

|

|

B11D9:16

|

Vehicle Battery: Circuit Voltage Below Threshold

|

GO to Pinpoint Test B

|

|

B11D9:17

|

Vehicle Battery: Circuit Voltage Above Threshold

|

GO to Pinpoint Test C

|

|

B1298:09

|

Steering Column Adjust Up Switch: Component Failure

|

REFER to:

Steering Column

(211-04 Steering Column, Diagnosis and Testing).

|

|

B1299:09

|

Steering Column Adjust Down Switch: Component Failure

|

REFER to:

Steering Column

(211-04 Steering Column, Diagnosis and Testing).

|

|

B12A1:09

|

Steering Column Adjust Out Switch: Component Failure

|

REFER to:

Steering Column

(211-04 Steering Column, Diagnosis and Testing).

|

|

B12A2:09

|

Steering Column Adjust In Switch: Component Failure

|

REFER to:

Steering Column

(211-04 Steering Column, Diagnosis and Testing).

|

|

B12F7:09

|

Single Wipe Switch: Component Failure

|

REFER to:

Wipers and Washers

(501-16 Wipers and Washers, Diagnosis and Testing).

|

|

B137F:09

|

Steering Wheel Left Switch Pack: Component Failure

|

REFER to:

Cruise Control

(419-03A Cruise Control, Diagnosis and Testing).

|

|

B137F:11

|

Steering Wheel Left Switch Pack: Circuit Short to Ground

|

REFER to:

Cruise Control

(419-03A Cruise Control, Diagnosis and Testing).

|

|

B137F:17

|

Steering Wheel Left Switch Pack: Circuit Voltage Above Threshold

|

REFER to:

Cruise Control

(419-03A Cruise Control, Diagnosis and Testing).

|

|

B1380:09

|

Steering Wheel Right Switch Pack: Component Failure

|

REFER to:

|

|

B1380:11

|

Steering Wheel Right Switch Pack: Circuit Short to Ground

|

REFER to:

|

|

B1380:17

|

Steering Wheel Right Switch Pack: Circuit Voltage Above Threshold

|

REFER to:

|

|

B13A6:09

|

Lane Departure Warning (LDW) Switch Input: Component Failure

|

REFER to:

Lane Departure Warning

(419-07 Lane Departure Warning, Diagnosis and Testing).

|

|

B1D36:09

|

Turn Indicator Switch: Component Failure

|

REFER to:

Turn Signal and Hazard Lamps

(417-01 Exterior Lighting, Diagnosis and Testing).

|

|

U2100:00

|

Initial Configuration Not Complete: No Sub Type Information

|

CHECK vehicle service history for recent service actions related to this module. This

sets due to incomplete or improper

procedures. If there have been recent service actions with this module, REPEAT/PERFORM the

procedure as directed by the diagnostic scan tool. If there have been no recent service actions, INSTALL a new module to

correct the failure to retain configuration data.

|

|

U2101:00

|

Control Module Configuration Incompatible: No Sub Type Information

|

This

sets if the steering wheel switches do not match the switch function configuration data in the

. CHECK the parts catalog and CONFIRM that the correct

and steering wheel control switches are installed in the vehicle. INSTALL the correct components, as necessary.

|

Chart

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices.

REFER to:

Diagnostic Methods

(100-00 General Information, Description and Operation).

Chart

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices.

REFER to:

Diagnostic Methods

(100-00 General Information, Description and Operation).

|

|

Description

|

Action

|

|

B135C:11

|

Heater Element: Circuit Short to Ground

|

GO to Pinpoint Test E

|

|

B135C:15

|

Heater Element: Circuit Short to Battery or Open

|

GO to Pinpoint Test E

|

|

U0100:00

|

Lost Communication With ECM/PCM "A": No Sub Type Operation

|

GO to Pinpoint Test F

|

|

U0140:00

|

Lost Communication With Body Control Module: No Sub Type Operation

|

GO to Pinpoint Test F

|

|

U0256:00

|

Lost Communication With Front Controls Interface Module "A": No Sub Type Operation

|

GO to Pinpoint Test F

|

|

U1000:00

|

Solid State Driver Protection Active - Driver Disabled: No Sub Type Operation

|

The

has temporarily disabled an output because an excessive current draw exists (such as a short to ground). The

cannot enable the output until the cause of the short is corrected. ADDRESS all other Diagnostic Trouble Codes (DTCs) first.

After the cause of the concern is corrected, CLEAR the Diagnostic Trouble Codes (DTCs). REPEAT the self-test.

|

|

U2100:00

|

Initial Configuration Not Complete: No Sub Type Operation

|

This

sets due to incomplete or improper

procedures. CARRY OUT the

procedure as directed by the diagnostic scan tool. Use As-Built data when carrying out

for this

.

|

|

U210A:11

|

Temperature Sensor: Circuit Short to Ground

|

GO to Pinpoint Test G

|

|

U210A:15

|

Temperature Sensor: Circuit Short to Battery or Open

|

GO to Pinpoint Test G

|

|

U3000:49

|

Control Module: Internal Electronic Failure

|

INSTALL a new

.

REFER to:

Heated Steering Wheel Module (HSWM)

(211-05 Steering Wheel and Column Electrical Components, Removal and Installation).

|

Symptom Chart

Symptom Chart: Steering Column Switches

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices.

REFER to:

Diagnostic Methods

(100-00 General Information, Description and Operation).

Symptom Chart

|

Condition

|

Possible Causes

|

Actions

|

|

No power in ON

|

-

Refer to the Pinpoint Test

|

GO to Pinpoint Test A

|

|

Key not detected is displayed in the message center

|

-

Refer to the Pinpoint Test

|

REFER to:

Passive Anti-Theft System (PATS)

(419-01B Passive Anti-Theft System (PATS) - Vehicles With: Push Button Start, Diagnosis and Testing).

|

|

The heated steering wheel is inoperative/does not operate correctly

|

-

Refer to the Pinpoint Test

|

GO to Pinpoint Test H

|

Pinpoint Tests

No Power in ON

Refer to Wiring Diagrams Cell 13 for schematic and connector information.

Refer to Wiring Diagrams Cell 20 for schematic and connector information.

Normal Operation and Fault Conditions

To place the vehicle in ON mode, locate the passive key inside the vehicle and press the ignition switch once, for at least

one second, without applying the brake pedal. When in ON mode, the

activates the integral run/start relay and provides a ground signal to activate the

run/start relay, which distributes fused voltage to various components. The integral run/start relay in the

receives voltage from high current

MEGA fuse 2 (125A). The

run/start relay receives voltage from the battery through the high current

. The

uses a Field Effect Transistor (FET) to control the relays.

To start the engine, locate the passive key inside the vehicle, position the selector lever into PARK or NEUTRAL, and press

the ignition switch while applying the brake pedal. When the ignition switch is pressed, a voltage signal is sent to the

and

. When the

detects the ignition switch is pressed, it begins the key initialization sequence by activating the front

antenna and the keyless entry rear antenna. Once the

detects a valid passive key is present, the

supplies power and ground to the starter relay.

Fault Trigger Conditions

|

|

Description

|

Fault Trigger Conditions

|

|

B108A:01

|

Start Button: General Electrical Failure

|

Sets if the

does not receive any signal from the ignition switch.

|

|

B108A:24

|

Start Button: Signal Stuck High

|

Sets if the

detects a short to voltage from the Start/Stop 1 input circuit from the push button ignition switch.

|

|

B1142:29

|

Ignition Status 1: Signal Invalid

|

This

sets when the

does not receive a valid ignition signal during a

self-test.

|

|

B1310:14

|

Run/Start Control: Circuit Short to Ground or Open

|

The

continuously monitors the control side of the run/start relay. This

sets if the

detects an open or a short to ground on the control circuit. The

uses a Field Effect Transistor (FET) to control the run/start relay. When this

sets, the control side of the run/start relay is disabled via the Field Effect Transistor (FET). Once the condition that

caused the

to set is repaired, the

must pass a self-test in order for the

to clear and the system to resume normal operation.

|

Possible Causes

-

Battery

-

Wiring, terminals or connectors

-

Fuse

-

Relay

-

Ignition switch (part of

)

-

Passive key

-

Keyless entry system concern

-

-

Visual Inspection and Diagnostic Pre-checks

-

Inspect the battery and battery cables.

-

Inspect high current

MEGA fuse 2 (125A).

-

Inspect

fuses 12 (7.5A) and 18 (5A).

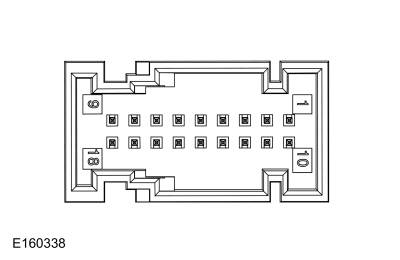

PINPOINT TEST A : NO POWER IN ON

| A1

CHECK FOR BCM (BODY CONTROL MODULE)

DIAGNOSTIC TROUBLE CODES (DTCS)

|

-

Using a diagnostic scan tool, carry out the

self-test.

-

Record all

Diagnostic Trouble Codes (DTCs).

Are any Diagnostic Trouble Codes (DTCs) present?

| Yes

|

If

B1310:14 is present, GO to

A2

If

B108A:01, B108A:24 or B1142:29 is present, GO to

A5

For all other

Diagnostic Trouble Codes (DTCs),

REFER to:

Body Control Module (BCM)

(419-10 Multifunction Electronic Modules, Diagnosis and Testing).

|

| No

|

If no Diagnostic Trouble Codes (DTCs) are present, GO to

A5

|

|

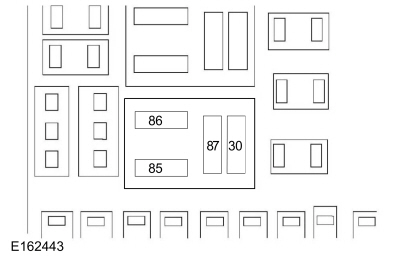

| A2

CHECK THE BJB (BATTERY JUNCTION BOX)

RUN/START RELAY

|

-

Remove the

run/start relay.

-

Carry out the appropriate relay component test.

Refer to Wiring Diagrams Cell 149 for schematic and connector information.

Is the relay OK?

| No

|

INSTALL a new

run/start relay.

|

|

| A3

CHECK THE RUN/START RELAY CONTROL CIRCUIT FOR A SHORT TO GROUND

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C2280C-25

|

|

Ground

|

Is the resistance less than 3 ohms?

|

| A4

CHECK THE RUN/START RELAY CONTROL CIRCUIT FOR AN OPEN

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C2280C-25

|

|

run/start relay, cavity 86

run/start relay, cavity 86

|

Is the resistance less than 3 ohms?

|

| A5

CONFIRM THE PASSIVE KEY ALLOWS VEHICLE ENTRY

|

|

NOTE:

Do not place the passive key inside the vehicle during this test step.

-

With the driver door unlocked and the passive key within 1 m (3.28 ft) of the driver door, press the button on the driver

door handle; the driver door should lock.

Did the driver door lock?

|

| A6

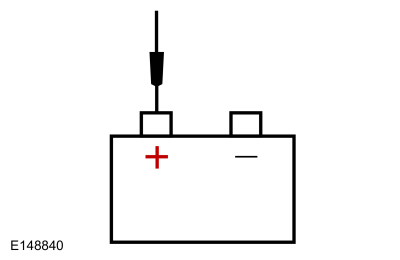

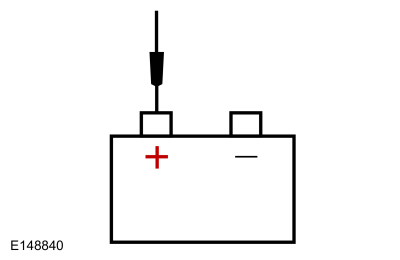

CHECK VEHICLE BATTERY

|

-

Carry out the Battery Condition Test.

REFER to:

Battery

(414-01 Battery, Mounting and Cables, Diagnosis and Testing).

Is the battery OK?

| No

|

CORRECT the battery condition and VERIFY correct charging operation.

REFER to:

Charging System

(414-00 Charging System - General Information, Diagnosis and Testing).

|

|

| A7

CHECK FOR IGNITION ON MODE

|

|

NOTE:

The airbag warning indicator in the message center only illuminates and proves out when the vehicle successfully enters ON

mode.

-

With the passive key in the vehicle, press the ignition switch for at least one second while monitoring the airbag warning

indicator in the message center.

Did the airbag warning indicator illuminate for approximately 6 seconds and then go out?

|

| A8

CARRY OUT A NETWORK TEST

|

-

Enter the following diagnostic mode on the diagnostic scan tool: Network Test.

Did the

pass the Network Test?

|

| A9

CHECK THE BCM (BODY CONTROL MODULE)

IGNITION SWITCH PARAMETER IDENTIFICATIONS (PIDS)

|

-

Enter the following diagnostic mode on the diagnostic scan tool:

Parameter Identification (PIDs).

-

While pressing the ignition switch, monitor the following Parameter Identifications (PIDs):

-

Start_Stop_1

-

Start_Stop_2

Did both PIDs change state when the switch was pressed?

|

| A10

CHECK THE IGNITION SWITCH

|

-

While pressing the ignition switch, measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

C3532, pin 5, component side

C3532, pin 5, component side

|

|

C3532, pin 9, component side

C3532, pin 9, component side

|

|

C3532, pin 5, component side

|

|

C3532, pin 18, component side

|

|

C3532, pin 7, component side

|

|

C3532, pin 1, component side

|

Are the resistances less than 3 ohms?

| No

|

INSTALL a new

(includes ignition switch).

REFER to:

Gearshift Module (GSM)

(307-05A Automatic Transmission External Controls - Vehicles With: 6-Speed Automatic Transmission - 6F50, Removal and Installation).

REFER to:

Gearshift Module (GSM)

(307-05A Automatic Transmission External Controls - Vehicles With: 6-Speed Automatic Transmission - 6F50, Removal and Installation).

|

|

| A11

CHECK FOR VOLTAGE AT THE IGNITION SWITCH

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C3532-1

|

|

Ground

|

Is the voltage greater than 11 volts?

| No

|

VERIFY

fuse 12 (7.5A) is OK. If OK, REPAIR the circuit. If not OK, REFER to the Wiring Diagrams manual to identify the possible

cause of the circuit short.

|

|

| A12

CHECK THE GROUND CIRCUIT TO THE IGNITION SWITCH

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C3532-9

|

|

Ground

|

|

C3532-18

|

|

Ground

|

Is the resistance less than 3 ohms?

|

| A13

CHECK THE START/STOP 1 INPUT CIRCUIT FOR A SHORT TO VOLTAGE

|

-

Disconnect

C1381B (2.0 GTDI).

-

Disconnect

C175B (all others).

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C3532-7

|

|

Ground

|

Is any voltage present?

|

| A14

CHECK THE IGNITION SWITCH CIRCUITS TO THE BCM (BODY CONTROL MODULE)

FOR A SHORT TO GROUND

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C3532-5

|

|

Ground

|

|

C3532-7

|

|

Ground

|

Are the resistances greater than 10,000 ohms?

| No

|

REPAIR the affected circuit(s).

|

|

| A15

CHECK THE IGNITION SWITCH CIRCUITS TO THE BCM (BODY CONTROL MODULE)

FOR AN OPEN

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C3532-5

|

|

C2280G-5

|

|

C3532-7

|

|

C2280G-51

|

Are the resistances less than 3 ohms?

| No

|

REPAIR the affected circuit(s).

|

|

| A16

CHECK THE CIRCUIT BETWEEN THE IGNITION SWITCH AND PCM (POWERTRAIN CONTROL MODULE)

FOR AN OPEN

|

-

Measure:

2.0L GTDI

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C3532-7

|

|

C1361B-47

|

All others

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C3532-7

|

|

C175B-16

|

Is the resistance less than 3 ohms?

|

| A17

CHECK FOR A SHORT BETWEEN THE IGNITION SWITCH CIRCUITS

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C3532-5

|

|

C3532-7

|

Is the resistance between these circuits greater than 10,000 ohms?

|

| A18

ATTEMPT VEHICLE START WHILE MONITORING THE MESSAGE CENTER

|

-

With the vehicle in PARK (automatic transmission) or NEUTRAL (automatic or manual transmission) and the passive key in the

vehicle, press the brake pedal and then press the ignition switch while monitoring the message center.

Did the engine crank?

| Yes

|

To diagnose the no start concern, Refer to Powertrain Control/Emissions Diagnosis (PC/ED) manual.

|

| No

|

If NO KEY DETECTED is displayed in the message center,

REFER to:

Passive Anti-Theft System (PATS)

(419-01B Passive Anti-Theft System (PATS) - Vehicles With: Push Button Start, Diagnosis and Testing).

If there is no message displayed in the message center, GO to

A19

|

|

| A19

CARRY OUT A NETWORK TEST

|

-

Enter the following diagnostic mode on the diagnostic scan tool: Network Test.

Did the

and

pass the network test?

|

| A20

CHECK FOR PCM (POWERTRAIN CONTROL MODULE)

AND BCM (BODY CONTROL MODULE)

DIAGNOSTIC TROUBLE CODES (DTCS)

|

-

Enter the following diagnostic mode on the diagnostic scan tool:

Self-Test.

-

Enter the following diagnostic mode on the diagnostic scan tool:

Self-Test.

Are any

or

Diagnostic Trouble Codes (DTCs) present?

| Yes

|

For

Diagnostic Trouble Codes (DTCs),

REFER to:

Electronic Engine Controls

(303-14A Electronic Engine Controls - 3.7L Duratec (227kW/301PS), Diagnosis and Testing).

REFER to:

Electronic Engine Controls

(303-14B Electronic Engine Controls - 2.0L EcoBoost (184kW/250PS) - MI4, Diagnosis and Testing).

Diagnostic Trouble Codes (DTCs),

REFER to:

Body Control Module (BCM)

(419-10 Multifunction Electronic Modules, Diagnosis and Testing).

|

|

| A21

CHECK FOR CORRECT BCM (BODY CONTROL MODULE)

OPERATION

|

-

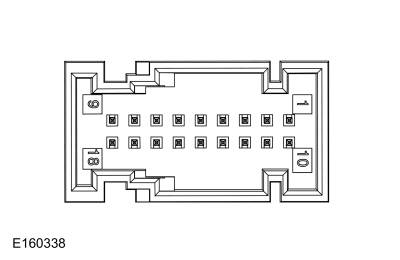

Disconnect and inspect all

connectors.

-

Repair:

-

corrosion (install new connector or terminals - clean module pins)

-

damaged or bent pins - install new terminals/pins

-

pushed-out pins - install new pins as necessary

-

Reconnect the

connectors and all other previously disconnected connectors. Make sure they seat and latch correctly.

-

Operate the system and determine if the concern is still present.

Is the concern still present?

| Yes

|

CHECK

for any applicable Technical Service Bulletins (TSBs). If a

exists for this concern, DISCONTINUE this test and FOLLOW

instructions. If no Technical Service Bulletins (TSBs) address this concern, INSTALL a new

.

REFER to:

Body Control Module (BCM)

(419-10 Multifunction Electronic Modules, Removal and Installation).

|

| No

|

The system is operating correctly at this time. The concern may have been caused by module connections. ADDRESS the root cause

of any connector or pin issues.

|

|

B11D9:16

Refer to Wiring Diagrams Cell 13 for schematic and connector information.

Normal Operation and Fault Conditions

The

continuously monitors input voltage for correct operation. If voltage outside of defined limits is detected by the

, the applicable

sets.

B11D9:16 can set if the vehicle battery has been discharged. The vehicle battery may become discharged due to excessive load(s)

on the charging system from aftermarket accessories or if the vehicle has been left unattended with the accessories on.

Fault Trigger Conditions

|

|

Description

|

Fault Trigger Conditions

|

|

B11D9:16

|

Vehicle Battery: Circuit Below Threshold

|

This

sets in continuous memory if the

detects battery voltage below 8 volts on the battery voltage supply circuit.

|

Possible Causes

-

Battery

-

Wiring, terminals or connectors

-

Fuse

-

Charging system

-

Visual Inspection and Diagnostic Pre-checks

-

Make sure the vehicle battery terminals and cables are free of any corrosion and other contaminates.

-

Make sure the vehicle battery terminals are tightened to their correct torque specifications.

-

Inspect

fuse 13 (7.5A).

PINPOINT TEST B : B11D9:16

| B1

CHECK FOR SCCM (STEERING COLUMN CONTROL MODULE)

DIAGNOSTIC TROUBLE CODES (DTCS)

|

-

Enter the following diagnostic mode on the diagnostic scan tool:

Self Test.

-

Enter the following diagnostic mode on the diagnostic scan tool:

Clear Diagnostic Trouble Codes (DTCs).

-

Enter the following diagnostic mode on the diagnostic scan tool:

Self Test.

Is

B119D:16 still present?

| No

|

The system is operating normally at this time. The

may have been set previously during battery charging or while jump starting the vehicle.

|

|

| B2

CHECK FOR CHARGING SYSTEM DIAGNOSTIC TROUBLE CODES (DTCS) IN THE PCM (POWERTRAIN CONTROL MODULE)

|

-

Enter the following diagnostic mode on the diagnostic scan tool:

Self Test.

-

Record all Continuous Memory Diagnostic Trouble Codes (CMDTCs) from the

.

Are any charging system Diagnostic Trouble Codes (DTCs) present in the

?

| Yes

|

DIAGNOSE the charging system Diagnostic Trouble Codes (DTCs).

REFER to:

Charging System

(414-00 Charging System - General Information, Diagnosis and Testing).

|

|

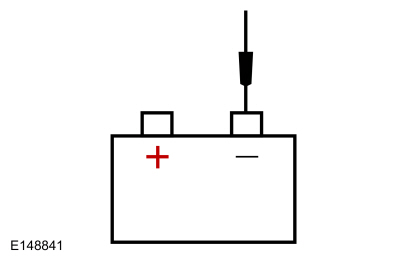

| B3

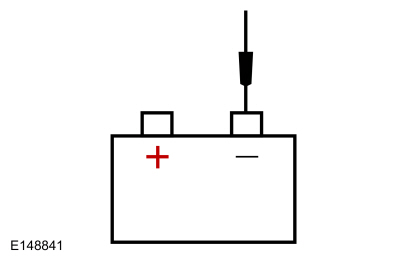

CHECK THE BATTERY CONDITION AND STATE OF CHARGE

|

-

Carry out the Battery Condition Test.

REFER to:

Battery

(414-01 Battery, Mounting and Cables, Diagnosis and Testing).

Is the battery OK?

| No

|

CHARGE the battery and REPEAT the battery condition test. If the battery does not pass the battery condition test, INSTALL

a new battery.

REFER to:

Battery

(414-01 Battery, Mounting and Cables, Removal and Installation).

|

|

| B4

CHECK THE SCCM (STEERING COLUMN CONTROL MODULE)

VOLTAGE SUPPLY

|

-

Measure and record:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

|

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C2414A-7

|

|

Ground

|

Is the voltage within 0.2 volt of the recorded battery voltage?

| No

|

VERIFY

fuse 13 (7.5A) is OK. If OK, REPAIR the affected circuit. If not OK, REFER to the Wiring Diagrams manual to identify the

possible causes of the circuit short.

|

|

| B5

CHECK THE SCCM (STEERING COLUMN CONTROL MODULE)

GROUND CIRCUIT

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C2414A-5

|

|

Ground

|

Is the resistance less than 3 ohms?

| Yes

|

CONNECT the battery negative cable. GO to

B6

|

| No

|

REPAIR the circuit. CONNECT the battery negative cable.

|

|

| B6

CHECK FOR CORRECT SCCM (STEERING COLUMN CONTROL MODULE)

OPERATION

|

-

Disconnect and inspect the

connectors.

-

Repair:

-

corrosion (install new connector or terminals - clean module pins)

-

damaged or bent pins - install new terminals/pins

-

pushed-out pins - install new pins as necessary

-

Reconnect the

connectors and all other previously disconnected connectors. Make sure they seat and latch correctly.

-

Operate the system and determine if the concern is still present.

Is the concern still present?

| Yes

|

CHECK

for any applicable Technical Service Bulletins (TSBs). If a

exists for this concern, DISCONTINUE this test and FOLLOW

instructions. If no Technical Service Bulletins (TSBs) address this concern, INSTALL a new

.

REFER to:

Steering Column Control Module (SCCM)

(211-05 Steering Wheel and Column Electrical Components, Removal and Installation).

|

| No

|

The system is operating correctly at this time. The concern may have been caused by module connections. ADDRESS the root cause

of any connector or pin issues.

|

|

B11D9:17

Refer to Wiring Diagrams Cell 13 for schematic and connector information.

Normal Operation and Fault Conditions

The

continuously monitors input voltage for correct operation. If voltage outside of defined limits is detected by the

, the applicable

sets.

B11D9:17 can set if the vehicle has been recently jump started or the vehicle battery has been recently charged.

Fault Trigger Conditions

|

|

Description

|

Fault Trigger Conditions

|

|

B11D9:17

|

Vehicle Battery: Circuit Above Threshold

|

This

sets in continuous memory if the

detects battery voltage above 19 volts on the battery voltage supply circuit.

|

Possible Causes

-

Wiring, terminals or connectors

-

Charging system

-

PINPOINT TEST C : B11D9:17

| C1

CHECK FOR HIGH BATTERY VOLTAGE AND/OR CHARGING SYSTEM DTC (DIAGNOSTIC TROUBLE CODE)

IN THE PCM (POWERTRAIN CONTROL MODULE)

|

-

Enter the following diagnostic mode on the diagnostic scan tool:

Self Test.

-

Record all

Continuous Memory Diagnostic Trouble Codes (CMDTCs).

Are any high battery voltage and/or charging system Diagnostic Trouble Codes (DTCs) present in the

?

| Yes

|

DIAGNOSE an overcharging condition. For non-

,

REFER to:

Charging System

(414-00 Charging System - General Information, Diagnosis and Testing).

For

,

REFER to: Direct Current/Direct Current (DC/DC) Converter Control Module (414-05 Voltage Converter/Inverter)

.

|

|

| C2

CHECK THE BATTERY VOLTAGE

|

-

Turn off all interior/exterior lights and accessories.

-

For non-

, start and run the engine at approximately 2,000 rpm for 3 minutes while monitoring the battery voltage.

Does the battery voltage rise to 16.5 volts or higher?

| Yes

|

DIAGNOSE the overcharging condition. For non-

,

REFER to:

Charging System

(414-00 Charging System - General Information, Diagnosis and Testing).

For

,

REFER to: Direct Current/Direct Current (DC/DC) Converter Control Module (414-05 Voltage Converter/Inverter)

.

|

|

| C3

RECHECK FOR SCCM (STEERING COLUMN CONTROL MODULE)

DTC (DIAGNOSTIC TROUBLE CODE)

B119D:17

|

-

Enter the following diagnostic mode on the diagnostic scan tool:

Self Test.

-

Clear the

Diagnostic Trouble Codes (DTCs) and repeat the self-test.

Is

B11D9:17 present in the

?

| No

|

The system is operating normally at this time. The

may have been set previously during battery charging or while jump starting the vehicle.

|

|

| C4

CHECK FOR CORRECT SCCM (STEERING COLUMN CONTROL MODULE)

OPERATION

|

-

Disconnect and inspect the

connectors.

-

Repair:

-

corrosion (install new connector or terminals - clean module pins)

-

damaged or bent pins - install new terminals/pins

-

pushed-out pins - install new pins as necessary

-

Reconnect the

connectors and all other previously disconnected connectors. Make sure they seat and latch correctly.

-

Operate the system and determine if the concern is still present.

Is the concern still present?

| Yes

|

CHECK

for any applicable Technical Service Bulletins (TSBs). If a

exists for this concern, DISCONTINUE this test and FOLLOW

instructions. If no Technical Service Bulletins (TSBs) address this concern, INSTALL a new

.

REFER to:

Steering Column Control Module (SCCM)

(211-05 Steering Wheel and Column Electrical Components, Removal and Installation).

|

| No

|

The system is operating correctly at this time. The concern may have been caused by module connections. ADDRESS the root cause

of any connector or pin issues.

|

|

B1310:12

Refer to Wiring Diagrams Cell 13 for schematic and connector information.

Normal Operation and Fault Conditions

When the ignition is placed in RUN mode, the

provides a ground for the coil (control) side of the run/start relay located in the

. The

monitors the run/start relay control circuit and sets a

if the circuit is shorted to voltage.

Fault Trigger Conditions

|

|

Description

|

Fault Trigger Conditions

|

|

B1310:12

|

Run/Start Control: Circuit Short to Battery

|

When this

sets, the control side of the run/start relay is disabled via the Field Effect Transistor (FET). Once the condition that

caused the

to set is repaired, the

must pass a self-test in order for the

to clear and the system to resume normal operation.

|

Possible Causes

-

Wiring, terminals or connectors

-

run/start relay

-

PINPOINT TEST D : B1310:12

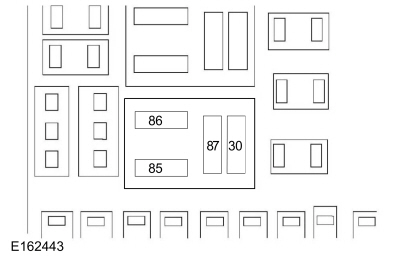

| D1

CHECK THE BJB (BATTERY JUNCTION BOX)

RUN/START RELAY

|

-

Remove the

run/start relay.

-

Carry out the appropriate relay component test.

Refer to Wiring Diagrams Cell 149 for schematic and connector information.

Is the relay OK?

| No

|

INSTALL a new

run/start relay.

|

|

| D2

CHECK THE RUN/START RELAY CONTROL CIRCUIT FOR A SHORT TO VOLTAGE

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C2280C-25

|

|

Ground

|

Is any voltage present?

|

| D3

CHECK FOR CORRECT BCM (BODY CONTROL MODULE)

OPERATION

|

-

Disconnect and inspect all

connectors.

-

Repair:

-

corrosion (install new connector or terminals - clean module pins)

-

damaged or bent pins - install new terminals/pins

-

pushed-out pins - install new pins as necessary

-

Reconnect the

connectors and all other previously disconnected connectors. Make sure they seat and latch correctly.

-

Operate the system and determine if the concern is still present.

Is the concern still present?

| Yes

|

CHECK

for any applicable Technical Service Bulletins (TSBs). If a

exists for this concern, DISCONTINUE this test and FOLLOW

instructions. If no Technical Service Bulletins (TSBs) address this concern, INSTALL a new

.

REFER to:

Body Control Module (BCM)

(419-10 Multifunction Electronic Modules, Removal and Installation).

|

| No

|

The system is operating correctly at this time. The concern may have been caused by module connections. ADDRESS the root cause

of any connector or pin issues.

|

|

B135C:11 and B135C:15

Refer to Wiring Diagrams Cell 128 for schematic and connector information.

Normal Operation and Fault Conditions

When steering wheel heat is requested, the

applies voltage and ground to the steering wheel heating element (integral to the steering wheel). The steering wheel heating

element draws between 1 and 10 amps of current depending on steering wheel temperature. The

uses a sensor in the steering wheel (integral to the steering wheel) to maintain the heated steering wheel temperature. The

is designed to remain on, heating the steering wheel and maintaining temperature until switched OFF on the

or until the ignition is turned OFF.

Fault Trigger Conditions

|

|

Description

|

Fault Trigger Conditions

|

|

B135C:11

|

Heater Element: Circuit Short to Ground

|

This

sets when the heated steering wheel is commanded on and the

senses current greater than 10 amps on the steering wheel heating element output circuit for greater than 80 ms, indicating

a short to ground. This

also sets when the steering wheel heating element output Field Effect Transistor (FET) in the

has a thermal failure. When this fault sets, the steering wheel heating element output is disabled until the ignition is

cycled.

|

|

B135C:15

|

Heater Element: Circuit Short to Battery or Open

|

This

sets when the heated steering wheel is commanded on and the module senses current less than 1 amp on the steering wheel heating

element output circuit for more than 80 ms. This indicates a short to voltage, an open circuit or an open circuit in the heating

element. When this fault sets, the steering wheel heating element output is disabled until the ignition is cycled.

|

Possible Causes

-

Wiring, terminals or connectors

-

Steering wheel

-

Clockspring

-

PINPOINT TEST E : B135C:11 AND B135C:15

| E1

CHECK THE HSWM (HEATED STEERING WHEEL MODULE)

DIAGNOSTIC TROUBLE CODES (DTCS)

|

-

Using a diagnostic scan tool, carry out the

self-test.

Is

B135C:11 present?

| No

|

For

B135C:15, GO to

E5

For all other Diagnostic Trouble Codes, REFER to the

Chart.

|

|

| E2

CHECK THE HEATER ELEMENT VOLTAGE CIRCUIT FOR A SHORT TO GROUND

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C2406-8

|

|

Ground

|

Is the resistance greater than 10,000 ohms?

|

| E3

CHECK THE HEATER ELEMENT VOLTAGE CIRCUIT FOR A SHORT TO GROUND

|

-

Remove the steering column shrouds to access the clockspring connectors.

REFER to:

Steering Column Shrouds

(501-05 Interior Trim and Ornamentation, Removal and Installation).

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C2406-8

|

|

Ground

|

Is the resistance greater than 10,000 ohms?

|

| E4

CHECK THE HEATER ELEMENT FOR A SHORT TO GROUND

|

-

Remove the driver airbag.

REFER to:

Driver Airbag

(501-20B Supplemental Restraint System, Removal and Installation).

-

Disconnect Clockspring C218E

.

-

On the steering wheel side, measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C218E-1

|

|

Ground

|

Is the resistance greater than 10,000 ohms?

| Yes

|

INSTALL a new clockspring.

REFER to:

Clockspring

(501-20B Supplemental Restraint System, Removal and Installation).

Using a diagnostic scan tool, CLEAR the

Diagnostic Trouble Codes (DTCs) and CARRY OUT the

self-test. If

B135C:11 or B135C:15 returns, INSTALL a new

.

REFER to:

Steering Column Control Module (SCCM)

(211-05 Steering Wheel and Column Electrical Components, Removal and Installation).

|

| No

|

INSTALL a new steering wheel.

REFER to:

Steering Wheel

(211-04 Steering Column, Removal and Installation).

|

|

| E5

CHECK THE HEATER ELEMENT VOLTAGE AND GROUND CIRCUIT FOR A SHORT TO VOLTAGE

|

-

Remove the steering column shrouds to access the clockspring connectors.

REFER to:

Steering Column Shrouds

(501-05 Interior Trim and Ornamentation, Removal and Installation).

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C2406-8

|

|

Ground

|

|

C2406-7

|

|

Ground

|

Is any voltage present?

| Yes

|

REPAIR the affected circuit.

|

|

| E6

CHECK THE HEATER ELEMENT AND CIRCUIT RESISTANCE

|

-

Connect

C2414C (if previously disconnected).

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C2406-7

|

|

C2406-8

|

Is the resistance between 1.6 and 3.1 ohms?

| No

|

If the resistance is less than 1.6 ohms, GO to

E7

If the resistance is more than 3.1 ohms, GO to

E8

|

|

| E7

CHECK THE HEATER ELEMENT CIRCUITS FOR A SHORT

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C2406-7

|

|

C2406-8

|

Is the resistance greater than 10,000 ohms?

| No

|

REPAIR the affected circuit.

|

|

| E8

CHECK THE HEATER ELEMENT CIRCUITS FOR AN OPEN

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C2406-7

|

|

C2414C-2

|

|

C2406-8

|

|

C2414C-1

|

Are the resistances less than 3 ohms?

| No

|

REPAIR the affected circuit.

|

|

| E9

CHECK THE HEATER ELEMENT RESISTANCE

|

-

Remove the driver airbag.

-

Disconnect Clockspring C218E

.

-

On the steering wheel side, measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C218E-1

|

|

C218E-2

|

Is the resistance between 1.6 and 3.1 ohms?

| Yes

|

INSTALL a new clockspring.

REFER to:

Clockspring

(501-20B Supplemental Restraint System, Removal and Installation).

Using a diagnostic scan tool, CLEAR the

Diagnostic Trouble Codes (DTCs) and CARRY OUT the

self-test. If

B135C:11 or B135C:15 returns, INSTALL a new

.

REFER to:

Steering Column Control Module (SCCM)

(211-05 Steering Wheel and Column Electrical Components, Removal and Installation).

|

| No

|

INSTALL a new steering wheel.

REFER to:

Steering Wheel

(211-04 Steering Column, Removal and Installation).

|

|

| E10

CHECK FOR CORRECT HSWM (HEATED STEERING WHEEL MODULE)

OPERATION

|

-

Inspect for the following and repair as necessary:

-

corrosion (install new connector or terminals - clean module pins)

-

damaged or bent pins - install new terminals/pins

-

pushed-out pins - install new pins as necessary

-

Connect

C2406 and all other previously disconnected connectors. Make sure they seat and latch correctly.

-

Using a diagnostic scan tool, clear all

Diagnostic Trouble Codes (DTCs).

-

Using a diagnostic scan tool, carry out the

self-test.

-

Operate the system and determine if the concern is still present.

Is the concern still present?

| Yes

|

CHECK

for any applicable Technical Service Bulletins (TSBs). If a

exists for this concern, DISCONTINUE this test and FOLLOW

instructions. If no Technical Service Bulletins (TSBs) address this concern, INSTALL a new

.

REFER to:

Heated Steering Wheel Module (HSWM)

(211-05 Steering Wheel and Column Electrical Components, Removal and Installation).

|

| No

|

The system is operating correctly at this time. The concern may have been caused by module connections. ADDRESS the root cause

of any connector or pin issues.

|

|

U0100:00, U0140:00, U0256:00

Normal Operation and Fault Conditions

The

communicates over the

with various modules. A

sets if the

does not receive an expected message from one of the modules within a predetermined period of time.

Fault Trigger Conditions

|

|

Description

|

Fault Trigger Conditions

|

|

U0100:00

|

Lost Communication With ECM/PCM "A": No Sub Type Information

|

This

sets when the

does not receive an expected message from the

for more than 5 seconds.

|

|

U0140:00

|

Lost Communication With Body Control Module: No Sub Type Information

|

This

sets when the

does not receive an expected message from the

for more than 5 seconds.

|

|

U0256:00

|

Lost Communication With Front Controls Interface Module "A": No Sub Type Information

|

This

sets when the

does not receive an expected message from the

for more than 5 seconds.

|

Possible Causes

PINPOINT TEST F : U0100:00, U0140:00, U0256:00

| F1

VERIFY THE CONCERN

|

-

Verify there is an observable symptom present.

Is an observable symptom present?

| No

|

The system is operating normally at this time. The

may have been set due to high network traffic or an intermittent fault condition.

|

|

| F2

CHECK THE COMMUNICATION NETWORK

|

-

Using a diagnostic scan tool, carry out a network test.

Do the

,

,

and

pass the network test?

| No

|

DIAGNOSE and REPAIR the communication concern.

REFER to:

Communications Network

(418-00 Module Communications Network, Diagnosis and Testing).

|

|

| F3

RETRIEVE THE RECORDED DIAGNOSTIC TROUBLE CODES (DTCS) FROM THE PCM (POWERTRAIN CONTROL MODULE)

, BCM (BODY CONTROL MODULE)

AND FCIM (FRONT CONTROLS INTERFACE MODULE)

SELF-TESTS

|

-

Using a diagnostic scan tool, carry out the

self-test.

-

Record any Diagnostic Trouble Codes (DTCs) retrieved from the self-test.

-

Using a diagnostic scan tool, carry out the

self-test.

-

Record any Diagnostic Trouble Codes (DTCs) retrieved from the self-test.

-

Using a diagnostic scan tool, carry out the

self-test.

-

Record any Diagnostic Trouble Codes (DTCs) retrieved from the self-test.

Is

U3003:16 or

U3003:17 recorded from any of the self-tests?

| Yes

|

For

Diagnostic Trouble Codes (DTCs),

REFER to:

Electronic Engine Controls

(303-14A Electronic Engine Controls - 3.7L Duratec (227kW/301PS), Diagnosis and Testing).

REFER to:

Electronic Engine Controls

(303-14B Electronic Engine Controls - 2.0L EcoBoost (184kW/250PS) - MI4, Diagnosis and Testing).

For

Diagnostic Trouble Codes (DTCs),

REFER to:

Body Control Module (BCM)

(419-10 Multifunction Electronic Modules, Diagnosis and Testing).

For

Diagnostic Trouble Codes (DTCs),

REFER to:

Information and Entertainment System

(415-00A Information and Entertainment System - General Information - Vehicles With: Touchscreen Display, Diagnosis and Testing).

REFER to:

Information and Entertainment System

(415-00B Information and Entertainment System - General Information - Vehicles With: THX Audio System, Diagnosis and Testing).

|

|

| F4

RECHECK THE HSWM (HEATED STEERING WHEEL MODULE)

DIAGNOSTIC TROUBLE CODES (DTCS)

|

|

NOTE:

If new modules were installed prior to the

being set, the module configuration may be incorrectly set during

or

may not have been carried out.

-

Using a diagnostic scan tool, clear all

Diagnostic Trouble Codes (DTCs).

Is

U0100:00, U0140:00 or U0256:00 still present?

| Yes

|

For

U0100:00, GO to

F5

For

U0140:00, GO to

F6

For

U0256:00, GO to

F7

|

| No

|

The system is operating correctly at this time. The

may have been set due to high network traffic or an intermittent fault condition.

|

|

| F5

CHECK FOR DTC (DIAGNOSTIC TROUBLE CODE)

U0100:00 SET IN OTHER MODULES

|

-

Using a diagnostic scan tool, clear all Diagnostic Trouble Codes (DTCs) in all modules.

-

Using a diagnostic scan tool, carry out the

self-test.

Is

U0100:00 set in the

?

|

| F6

CHECK FOR DTC (DIAGNOSTIC TROUBLE CODE)

U0140:00 SET IN OTHER MODULES

|

-

Using a diagnostic scan tool, clear all Diagnostic Trouble Codes (DTCs) in all modules.

-

Using a diagnostic scan tool, carry out the

self-test.

Is

U0140:00 set in the

?

|

| F7

CHECK FOR DTC (DIAGNOSTIC TROUBLE CODE)

U0256:00 SET IN OTHER MODULES

|

-

Using a diagnostic scan tool, clear all Diagnostic Trouble Codes (DTCs) in all modules.

-

Using a diagnostic scan tool, carry out the

self-test.

Is

U0256:00 set in the

?

|

| F8

CHECK FOR CORRECT HSWM (HEATED STEERING WHEEL MODULE)

OPERATION

|

-

Disconnect and inspect

C2406.

-

Inspect for the following and repair as necessary:

-

corrosion (install new connector or terminals - clean module pins)

-

damaged or bent pins - install new terminals/pins

-

pushed-out pins - install new pins as necessary

-

Reconnect

C2406 and all other previously disconnected connectors. Make sure they seat and latch correctly.

-

Using a diagnostic scan tool, clear all

Diagnostic Trouble Codes (DTCs).

-

Using a diagnostic scan tool, carry out the

self-test.

-

Operate the system and determine if the concern is still present.

Is the concern still present?

| Yes

|

CHECK

for any applicable Technical Service Bulletins (TSBs). If a

exists for this concern, DISCONTINUE this test and FOLLOW

instructions. If no Technical Service Bulletins (TSBs) address this concern, INSTALL a new

.

REFER to:

Heated Steering Wheel Module (HSWM)

(211-05 Steering Wheel and Column Electrical Components, Removal and Installation).

|

| No

|

The system is operating correctly at this time. The concern may have been caused by module connections. ADDRESS the root cause

of any connector or pin issues.

|

|

| F9

CHECK FOR CORRECT PCM (POWERTRAIN CONTROL MODULE)

OPERATION

|

-

Disconnect and inspect all

connectors.

-

Inspect for the following and repair as necessary:

-

corrosion (install new connector or terminals - clean module pins)

-

damaged or bent pins - install new terminals/pins

-

pushed-out pins - install new pins as necessary

-

Reconnect the

connectors and all other previously disconnected connectors. Make sure they seat and latch correctly.

-

Using a diagnostic scan tool, clear all

Diagnostic Trouble Codes (DTCs).

-

Using a diagnostic scan tool, carry out the

self-test.

-

Operate the system and determine if the concern is still present.

Is the concern still present?

| Yes

|

CHECK

for any applicable Technical Service Bulletins (TSBs). If a

exists for this concern, DISCONTINUE this test and FOLLOW

instructions. If no Technical Service Bulletins (TSBs) address this concern, INSTALL a new

.

REFER to:

Powertrain Control Module (PCM)

(303-14A Electronic Engine Controls - 3.7L Duratec (227kW/301PS), Removal and Installation).

REFER to:

Powertrain Control Module (PCM)

(303-14B Electronic Engine Controls - 2.0L EcoBoost (184kW/250PS) - MI4, Removal and Installation).

|

| No

|

The system is operating correctly at this time. The concern may have been caused by module connections. ADDRESS the root cause

of any connector or pin issues.

|

|

| F10

CHECK FOR CORRECT BCM (BODY CONTROL MODULE)

OPERATION

|

-

Disconnect and inspect all

connectors.

-

Inspect for the following and repair as necessary:

-

corrosion (install new connector or terminals - clean module pins)

-

damaged or bent pins - install new terminals/pins

-

pushed-out pins - install new pins as necessary

-

Reconnect the

connectors and all other previously disconnected connectors. Make sure they seat and latch correctly.

-

Using a diagnostic scan tool, clear all

Diagnostic Trouble Codes (DTCs).

-

Using a diagnostic scan tool, carry out the

self-test.

-

Operate the system and determine if the concern is still present.

Is the concern still present?

| Yes

|

CHECK

for any applicable Technical Service Bulletins (TSBs). If a

exists for this concern, DISCONTINUE this test and FOLLOW

instructions. If no Technical Service Bulletins (TSBs) address this concern, INSTALL a new

REFER to:

Body Control Module (BCM)

(419-10 Multifunction Electronic Modules, Removal and Installation).

.

|

| No

|

The system is operating correctly at this time. The concern may have been caused by module connections. ADDRESS the root cause

of any connector or pin issues.

|

|

| F11

CHECK FOR CORRECT FCIM (FRONT CONTROLS INTERFACE MODULE)

OPERATION

|

-

Disconnect and inspect all

connectors.

-

Inspect for the following and repair as necessary:

-

corrosion (install new connector or terminals - clean module pins)

-

damaged or bent pins - install new terminals/pins

-

pushed-out pins - install new pins as necessary

-

Reconnect the

connectors and all other previously disconnected connectors. Make sure they seat and latch correctly.

-

Using a diagnostic scan tool, clear all

Diagnostic Trouble Codes (DTCs).

-

Using a diagnostic scan tool, carry out the

self-test.

-

Operate the system and determine if the concern is still present.

Is the concern still present?

| Yes

|

CHECK

for any applicable Technical Service Bulletins (TSBs). If a

exists for this concern, DISCONTINUE this test and FOLLOW

instructions. If no Technical Service Bulletins (TSBs) address this concern, INSTALL a new

.

REFER to:

Front Controls Interface Module (FCIM)

(415-00A Information and Entertainment System - General Information - Vehicles With: Touchscreen Display, Removal and Installation).

REFER to:

Front Controls Interface Module (FCIM)

(415-00B Information and Entertainment System - General Information - Vehicles With: THX Audio System, Removal and Installation).

|

| No

|

The system is operating correctly at this time. The concern may have been caused by module connections. ADDRESS the root cause

of any connector or pin issues.

|

|

U210A:11 and U210A:15

Refer to Wiring Diagrams Cell 128 for schematic and connector information.

Normal Operation and Fault Conditions

When steering wheel heat is requested, the

uses a sensor in the steering wheel (integral to the steering wheel) to maintain the heated steering wheel temperature. The

resistance of the sensor rises as the temperature falls and the resistance falls as the temperature rises. The resistance

can vary from 3,384 ohms at 50°C (122°F) to 34,699 ohms at 0°C (32°F). The

supplies a reference voltage and ground to the temperature sensor and monitors the voltage drop from the temperature sensor

for controlling current flow to the heating element. The

is designed to remain on, heating the steering wheel and maintaining temperature, until switched OFF on the

or the ignition is turned OFF.

Fault Trigger Conditions

|

|

Description

|

Fault Trigger Conditions

|

|

U210A:11

|

Temperature Sensor: Circuit Short to Ground

|

This

only sets when the heated steering wheel is commanded on and the

reads a resistance value less than 627 ohms on the heating element temperature sensor input circuit for greater than 1 second,

indicating a short to ground. When this fault occurs, the steering wheel heating element output is disabled until the ignition

is cycled.

|

|

U210A:15

|

Temperature Sensor: Circuit Short to Battery or Open

|

This

only sets when the heated steering wheel is commanded on and the

reads a resistance value greater than 670,000 ohms on the heating element temperature sensor reference circuit for greater

than 10 minutes. This indicates a short to voltage, an open circuit or an open heating element temperature sensor. When this

fault occurs, the steering wheel heating element output is disabled until the ignition is cycled.

|

Possible Causes

-

Wiring, terminals or connectors

-

Steering wheel

-

Clockspring

-

PINPOINT TEST G : U210A:11 AND U210A:15

| G1

CHECK THE HSWM (HEATED STEERING WHEEL MODULE)

DIAGNOSTIC TROUBLE CODES (DTCS)

|

-

Using a diagnostic scan tool, carry out the

self-test.

Is

U210A:11 present?

| No

|

For

U210A:15, GO to

G5

For all other Diagnostic Trouble Codes (DTCs), REFER to the

Chart.

|

|

| G2

CHECK THE HEATER ELEMENT TEMPERATURE SENSOR REFERENCE CIRCUIT FOR A SHORT TO GROUND

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C2406-5

|

|

Ground

|

Is the resistance greater than 10,000 ohms?

|

| G3

CHECK THE HEATER ELEMENT TEMPERATURE SENSOR REFERENCE CIRCUIT FOR A SHORT TO GROUND

|

-

Remove the steering column shrouds to access the clockspring connectors.

REFER to:

Steering Column Shrouds

(501-05 Interior Trim and Ornamentation, Removal and Installation).

-

Disconnect Clockspring C218A

.

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C2406-5

|

|

Ground

|

Is the resistance greater than 10,000 ohms?

|

| G4

CHECK THE HEATER ELEMENT TEMPERATURE SENSOR FOR A SHORT TO GROUND

|

-

Remove the driver airbag.

REFER to:

Driver Airbag

(501-20B Supplemental Restraint System, Removal and Installation).

-

Disconnect Clockspring C218B

.

-

On the steering wheel side, measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C218B-1

|

|

Ground

|

Is the resistance greater than 10,000 ohms?

| Yes

|

INSTALL a new clockspring.

REFER to:

Clockspring

(501-20B Supplemental Restraint System, Removal and Installation).

|

| No

|

INSTALL a new steering wheel.

REFER to:

Steering Wheel

(211-04 Steering Column, Removal and Installation).

|

|

| G5

CHECK THE HEATER ELEMENT TEMPERATURE SENSOR REFERENCE AND GROUND CIRCUIT FOR A SHORT TO VOLTAGE

|

-

Remove the steering column shrouds to access the clockspring connectors.

REFER to:

Steering Column Shrouds

(501-05 Interior Trim and Ornamentation, Removal and Installation).

-

Disconnect Clockspring C218A

.

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C2406-5

|

|

Ground

|

|

C2406-12

|

|

Ground

|

Is any voltage present?

|

| G6

CHECK THE HEATER ELEMENT TEMPERATURE SENSOR AND CIRCUIT RESISTANCE

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C2406-5

|

|

C2406-12

|

Is the resistance between 627 and 670,000 ohms?

| No

|

If the resistance is less than 627 ohms, GO to

G7

If the resistance is greater than 670,000 ohms, GO to

G8

|

|

| G7

CHECK THE HEATER ELEMENT TEMPERATURE SENSOR CIRCUITS FOR A SHORT TOGETHER

|

-

Disconnect Clockspring C218A

.

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C2406-5

|

|

C2406-12

|

Is the resistance greater than 10,000 ohms?

|

| G8

CHECK THE HEATER ELEMENT TEMPERATURE SENSOR CIRCUITS FOR AN OPEN

|

-

Disconnect Clockspring C218A

.

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C2406-5

|

|

C218A-3

|

|

C2406-12

|

|

C218A-2

|

Are the resistances less than 3 ohms?

| No

|

REPAIR the affected circuit.

|

|

| G9

CHECK THE HEATER ELEMENT TEMPERATURE SENSOR RESISTANCE

|

-

Remove the driver airbag.

REFER to:

Driver Airbag

(501-20B Supplemental Restraint System, Removal and Installation).

-

Disconnect Clockspring C218B

.

-

On the steering wheel side, measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C218B-1

|

|

C218B-2

|

Is the resistance between 627 and 670,000 ohms?

| Yes

|

INSTALL a new clockspring.

REFER to:

Clockspring

(501-20B Supplemental Restraint System, Removal and Installation).

|

| No

|

INSTALL a new steering wheel.

REFER to:

Steering Wheel

(211-04 Steering Column, Removal and Installation).

|

|

| G10

CHECK FOR CORRECT HSWM (HEATED STEERING WHEEL MODULE)

OPERATION

|

-

Inspect for the following and repair as necessary:

-

corrosion (install new connector or terminals - clean module pins)

-

damaged or bent pins - install new terminals/pins

-

pushed-out pins - install new pins as necessary

-

Reconnect all other previously disconnected connectors. Make sure all connectors are seated and latched correctly.

-

Using a diagnostic scan tool, clear all

Diagnostic Trouble Codes (DTCs).

-

Using a diagnostic scan tool, carry out the

self-test.

-

Operate the system and determine if the concern is still present.

Is the concern still present?

| Yes

|

CHECK

for any applicable Technical Service Bulletins (TSBs). If a

exists for this concern, DISCONTINUE this test and FOLLOW

instructions. If no Technical Service Bulletins (TSBs) address this concern, INSTALL a new

.

REFER to:

Heated Steering Wheel Module (HSWM)

(211-05 Steering Wheel and Column Electrical Components, Removal and Installation).

|

| No

|

The system is operating correctly at this time. The concern may have been caused by module connections. ADDRESS the root cause

of any connector or pin issues.

|

|

The Heated Steering Wheel Is Inoperative/Does Not Operate Correctly

Refer to Wiring Diagrams Cell 128 for schematic and connector information.

Normal Operation and Fault Conditions

When steering wheel heat is requested, the

uses a sensor in the steering wheel (integral to the steering wheel) to maintain the heated steering wheel temperature. The

resistance of the sensor rises as the temperature falls and the resistance falls as the temperature rises. The resistance

can vary from 3,384 ohms at 50°C (122°F) to 34,699 ohms at 0°C (32°F). The

supplies a reference voltage and ground to the temperature sensor and monitors the voltage drop from the temperature sensor

for controlling current flow to the heating element. The

is designed to remain on, heating the steering wheel and maintaining temperature until switched OFF on the

or the ignition is turned OFF.

NOTE:

On all vehicles, slow heating between the 10 o'clock and 2 o'clock steering wheel hand positions is considered normal.

Possible Causes

-

Wiring, terminals or connectors

-

Steering wheel

-

Clockspring

-

PINPOINT TEST H : THE HEATED STEERING WHEEL IS INOPERATIVE/DOES NOT OPERATE CORRECTLY

| H1

CHECK THE HSWM (HEATED STEERING WHEEL MODULE)

DIAGNOSTIC TROUBLE CODES (DTCS)

|

-

Using a diagnostic scan tool, carry out the

self-test.

Are any Diagnostic Trouble Codes (DTCs) present?

| Yes

|

REFER to the

Chart to diagnose the

Diagnostic Trouble Codes (DTCs).

|

|

| H2

CHECK THE HEATER ELEMENT TEMPERATURE SENSOR REFERENCE CIRCUIT FOR A SHORT TO TO GROUND

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C2406-5

|

|

Ground

|

Is the resistance greater than 10,000 ohms?

|

| H3

CHECK THE HEATER ELEMENT TEMPERATURE SENSOR CIRCUITS FOR A SHORT TO GROUND

|

-

Remove the steering column shrouds to access the clockspring connectors.

REFER to:

Steering Column Shrouds

(501-05 Interior Trim and Ornamentation, Removal and Installation).

-

Disconnect Clockspring C218A

.

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C2406-5

|

|

Ground

|

|

C2406-12

|

|

Ground

|

Are the resistances greater than 10,000 ohms?

| No

|

REPAIR the affected circuit.

|

|

| H4

CHECK THE HEATER ELEMENT TEMPERATURE SENSOR FOR A SHORT TO GROUND

|

-

Remove the driver airbag.

REFER to:

Driver Airbag

(501-20B Supplemental Restraint System, Removal and Installation).

-

Disconnect Clockspring C218B

.

-

On the steering wheel side, measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C218B-1

|

|

Ground

|

|

C218B-2

|

|

Ground

|

Are the resistances greater than 10,000 ohms?

| Yes

|

INSTALL a new clockspring.

REFER to:

Clockspring

(501-20B Supplemental Restraint System, Removal and Installation).

|

| No

|

INSTALL a new steering wheel.

REFER to:

Steering Wheel

(211-04 Steering Column, Removal and Installation).

|

|

| H5

CHECK THE HEATER ELEMENT TEMPERATURE SENSOR AND CIRCUIT RESISTANCE

|

-

Measure and record:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C2406-5

|

|

C2406-12

|

-

Compare the recorded measurement value with the table shown.

|

Ambient Temperature

|

Resistance

|

|

0-10°C (32-50°F)

|

18,754-34,699 ohms

|

|

10-20°C (50-68°F)

|

11,831-21,046 ohms

|

|

20-25°C (68-77°F)

|

9,500-13,149 ohms

|

|

25-30°C (77-86°F)

|

7,632-10,500 ohms

|

|

30-35°C (86-95°F)

|

6,173-8,482 ohms

|

|

35-40°C (95-104°F)

|

5,024-6,889 ohms

|

|

40-50°C (104-122°F)

|

3,384-5,630 ohms

|

Is the resistance within the specified values for the temperature?

|

| H6

CHECK THE HEATER ELEMENT TEMPERATURE SENSOR CIRCUITS FOR A SHORT

|

-

Remove the steering column shrouds to access the clockspring connectors.

REFER to:

Steering Column Shrouds

(501-05 Interior Trim and Ornamentation, Removal and Installation).

-

Disconnect Clockspring C218A

.

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C2406-5

|

|

C2406-12

|

Is the resistance greater than 10,000 ohms?

| No

|

REPAIR the affected circuit.

|

|

| H7

CHECK THE HEATER ELEMENT TEMPERATURE SENSOR RESISTANCE

|

-

Remove the driver airbag.

REFER to:

Driver Airbag

(501-20B Supplemental Restraint System, Removal and Installation).

-

Disconnect Clockspring C218B

.

-

On the steering wheel side, measure and record:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C218B-1

|

|

C218B-2

|

-

Compare the recorded measurement value with the table shown.

|

Ambient Temperature

|

Resistance

|

|

0-10°C (32-50°F)

|

18,754-34,699 ohms

|

|

10-20°C (50-68°F)

|

11,831-21,046 ohms

|

|

20-25°C (68-77°F)

|

9,500-13,149 ohms

|

|

25-30°C (77-86°F)

|

7,632-10,500 ohms

|

|

30-35°C (86-95°F)

|

6,173-8,482 ohms

|

|

35-40°C (95-104°F)

|

5,024-6,889 ohms

|

|

40-50°C (104-122°F)

|

3,384-5,630 ohms

|

Is the resistance within the specified values for the temperature?

| Yes

|

INSTALL a new clockspring.

REFER to:

Clockspring

(501-20B Supplemental Restraint System, Removal and Installation).

|

| No

|

INSTALL a new steering wheel.

REFER to:

Steering Wheel

(211-04 Steering Column, Removal and Installation).

|

|

| H8

CHECK FOR CORRECT HSWM (HEATED STEERING WHEEL MODULE)

OPERATION

|

-

Inspect for the following and repair as necessary:

-

corrosion (install new connector or terminals - clean module pins)

-

damaged or bent pins - install new terminals/pins

-

pushed-out pins - install new pins as necessary

-

Reconnect all other previously disconnected connectors. Make sure all connectors are seated and latched correctly.

-

Using a diagnostic scan tool, clear all

Diagnostic Trouble Codes (DTCs).

-

Using a diagnostic scan tool, carry out the

self-test.

-

Operate the system and determine if the concern is still present.

Is the concern still present?

| Yes

|

CHECK

for any applicable Technical Service Bulletins (TSBs). If a

exists for this concern, DISCONTINUE this test and FOLLOW

instructions. If no Technical Service Bulletins (TSBs) address this concern, INSTALL a new

.

REFER to:

Heated Steering Wheel Module (HSWM)

(211-05 Steering Wheel and Column Electrical Components, Removal and Installation).

|

| No

|

The system is operating correctly at this time. The concern may have been caused by module connections. ADDRESS the root cause

of any connector or pin issues.

|

|