| 417-01 Exterior Lighting

|

2013 - 2014 MKZ

|

| Diagnosis and Testing

|

Procedure revision date:

04/1/2013

|

Headlamps

DTC Chart: Body Control Module (BCM)

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices.

REFER to:

Diagnostic Methods

(100-00 General Information, Description and Operation).

Chart

DTC Chart: Headlamp Control module (HCM)

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices.

REFER to:

Diagnostic Methods

(100-00 General Information, Description and Operation).

Headlamp Control module (HCM)

Chart

|

DTC

|

Description

|

Action

|

|

B103C:01

|

Left Headlamp Control: General Electrical Failure

|

INSTALL a new headlamp assembly.

REFER to:

Headlamp Assembly

(417-01 Exterior Lighting, Removal and Installation).

|

|

B103C:13

|

Left Headlamp Control: Circuit Open

|

INSTALL a new headlamp assembly.

REFER to:

Headlamp Assembly

(417-01 Exterior Lighting, Removal and Installation).

|

|

B103D:01

|

Right Headlamp Control: General Electrical Failure

|

INSTALL a new headlamp assembly.

REFER to:

Headlamp Assembly

(417-01 Exterior Lighting, Removal and Installation).

|

|

B103D:13

|

Right Headlamp Control: Circuit Open

|

INSTALL a new headlamp assembly.

REFER to:

Headlamp Assembly

(417-01 Exterior Lighting, Removal and Installation).

|

|

B1087:83

|

LIN Bus "A": Value of Signal Protection Calculation Incorrect

|

GO to Pinpoint Test G G

|

|

B1087:86

|

LIN Bus "A": Signal Invalid

|

GO to Pinpoint Test G G

|

|

B1088:83

|

LIN Bus "B": Value of Signal Protection Calculation Incorrect

|

GO to Pinpoint Test G G

|

|

B1088:86

|

LIN Bus "B": Signal Invalid

|

GO to Pinpoint Test G G

|

|

B11F1:54

|

Swiveling Control: Missing Calibration

|

INSTALL a new headlamp assembly.

REFER to:

Headlamp Assembly

(417-01 Exterior Lighting, Removal and Installation).

|

|

B1D64:01

|

Left Headlamp Swiveling Motor: General Electrical Failure

|

INSTALL a new headlamp assembly.

REFER to:

Headlamp Assembly

(417-01 Exterior Lighting, Removal and Installation).

|

|

B1D64:64

|

Left Headlamp Swiveling Motor: Signal Plausibility Failure

|

INSTALL a new headlamp assembly.

REFER to:

Headlamp Assembly

(417-01 Exterior Lighting, Removal and Installation).

|

|

B1D64:87

|

Left Headlamp Swiveling Motor: Missing Message

|

INSTALL a new headlamp assembly.

REFER to:

Headlamp Assembly

(417-01 Exterior Lighting, Removal and Installation).

|

|

B1D65:01

|

Right Headlamp Swiveling Motor: General Electrical Failure

|

INSTALL a new headlamp assembly.

REFER to:

Headlamp Assembly

(417-01 Exterior Lighting, Removal and Installation).

|

|

B1D65:64

|

Right Headlamp Swiveling Motor: Signal Plausibility Failure

|

INSTALL a new headlamp assembly.

REFER to:

Headlamp Assembly

(417-01 Exterior Lighting, Removal and Installation).

|

|

B1D65:87

|

Right Headlamp Swiveling Motor: Missing Message

|

INSTALL a new headlamp assembly.

REFER to:

Headlamp Assembly

(417-01 Exterior Lighting, Removal and Installation).

|

|

B1D68:64

|

Left Headlamp Swiveling Feedback Sensor: Signal Plausibility Failure

|

INSTALL a new headlamp assembly.

REFER to:

Headlamp Assembly

(417-01 Exterior Lighting, Removal and Installation).

|

|

B1D69:64

|

Right Headlamp Swiveling Feedback Sensor: Signal Plausibility Failure

|

INSTALL a new headlamp assembly.

REFER to:

Headlamp Assembly

(417-01 Exterior Lighting, Removal and Installation).

|

|

U0100:00

|

Lost Communication With ECM/PCM "A": No Sub Type Information

|

GO to Pinpoint Test H H

|

|

U0121:00

|

Lost Communication With Anti-Lock Brake System (ABS) Control Module: No Sub Type Information

|

GO to Pinpoint Test I I

|

|

U0140:00

|

Lost Communication With Body Control Module: No Sub Type Information

|

GO to Pinpoint Test J J

|

|

U0300:00

|

Internal Control Module Software Incompatibility: No Sub Type Information

|

CHECK the vehicle service history for recent service actions related to this module. This

sets due to incomplete or incorrect Programmable Module Installation (PMI) procedures. If there have been recent service

actions with this module, REPEAT the Programmable Module Installation (PMI) procedure as directed by the scan tool.

REFER to:

Module Configuration - System Operation and Component Description

(418-01 Module Configuration, Description and Operation).

If there have been no recent service actions, INSTALL a new Headlamp Control Module (HCM).

|

|

U0401:00

|

Invalid Data Received from ECM/PCM A: No Sub Type Information

|

This

sets when the Headlamp Control Module (HCM) receives invalid network data from the

. RETRIEVE and REPAIR all non-network Diagnostic Trouble Codes (DTCs) in the

and other modules on the network. Refer to Powertrain Control/Emissions Diagnosis (PC/ED) manual.

|

|

U0415:00

|

Invalid Data Received From Anti-Lock Brake System (ABS) Control Module: No Sub Type Information

|

This

sets when the Headlamp Control Module (HCM) receives invalid network data from the

module. RETRIEVE and REPAIR all non-network Diagnostic Trouble Codes (DTCs) in the

module and other modules on the network.

REFER to:

Anti-Lock Brake System (ABS) and Stability Control - Vehicles Built From: 20-May-2013

(206-09 Anti-Lock Brake System (ABS) and Stability Control, Diagnosis and Testing).

|

|

U0416:00

|

Invalid Data Received From Vehicle Dynamics Control Module: No Sub Type Information

|

This

sets when the Headlamp Control Module (HCM) receives invalid network data from the

. RETRIEVE and REPAIR all non-network Diagnostic Trouble Codes (DTCs) in the

and other modules on the network.

REFER to:

Vehicle Dynamic Suspension

(204-05 Vehicle Dynamic Suspension, Diagnosis and Testing).

|

|

U0422:00

|

Invalid Data Received From Body Control Module: No Sub Type Information

|

This

sets when the Headlamp Control Module (HCM) receives invalid network data from the

. RETRIEVE and REPAIR all non-network Diagnostic Trouble Codes (DTCs) in the

and other modules on the network.

REFER to:

Body Control Module (BCM)

(419-10 Multifunction Electronic Modules, Diagnosis and Testing).

|

|

U0452:00

|

Invalid Data Received From Restraints Control Module: No Sub Type Information

|

This

sets when the Headlamp Control Module (HCM) receives invalid network data from the

. RETRIEVE and REPAIR all non-network Diagnostic Trouble Codes (DTCs) in the

and other modules on the network.

REFER to:

Airbag Supplemental Restraint System (SRS)

(501-20B Supplemental Restraint System, Diagnosis and Testing).

|

|

U2100:00

|

Initial Configuration Not Complete: No Sub Type Information

|

CHECK the vehicle service history for recent service actions related to this module. This

sets due to incomplete or incorrect Programmable Module Installation (PMI) procedures. If there have been recent service

actions with this module, REPEAT the Programmable Module Installation (PMI) procedure as directed by the scan tool.

REFER to:

Module Configuration - System Operation and Component Description

(418-01 Module Configuration, Description and Operation).

If there have been no recent service actions, INSTALL a new Headlamp Control Module (HCM) to correct the failure to retain

configuration data.

|

|

U2101:00

|

Control Module Configuration Incompatible: No Sub Type Information

|

CHECK the vehicle service history for recent service actions related to this module. This

sets due to incomplete or incorrect Programmable Module Installation (PMI) procedures. If there have been recent service

actions with this module, REPEAT the Programmable Module Installation (PMI) procedure as directed by the scan tool.

REFER to:

Module Configuration - System Operation and Component Description

(418-01 Module Configuration, Description and Operation).

If there have been no recent service actions, INSTALL a new Headlamp Control Module (HCM).

|

|

U3000:45

|

Control Module: Program Memory Failure

|

CLEAR the

. REPEAT the self-test. If the

returns, INSTALL a new Headlamp Control Module (HCM).

|

|

U3000:46

|

Control Module: Calibration / Parameter Memory Failure

|

CLEAR the

. REPEAT the self-test. If the

returns, INSTALL a new Headlamp Control Module (HCM).

|

DTC Chart: Steering Column Control Module (SCCM)

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices.

REFER to:

Diagnostic Methods

(100-00 General Information, Description and Operation).

Chart

|

DTC

|

Description

|

Action

|

|

B1007:09

|

High-Beam Headlamp Switch: Component Failure

|

INSTALL a new

steering column multifunction switch.

REFER to:

Steering Column Multifunction Switch LH

(211-05 Steering Wheel and Column Electrical Components, Removal and Installation).

TEST the system for normal operation. If the concern still exists, INSTALL a new

.

REFER to:

Steering Column Control Module (SCCM)

(211-05 Steering Wheel and Column Electrical Components, Removal and Installation).

|

|

All other

Diagnostic Trouble Codes (DTCs)

|

-

|

REFER to:

Steering Wheel and Column Electrical Components

(211-05 Steering Wheel and Column Electrical Components, Diagnosis and Testing).

|

DTC Chart: Image Processing Module - A (IPM-A)

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices.

REFER to:

Diagnostic Methods

(100-00 General Information, Description and Operation).

Chart

|

DTC

|

Description

|

Action

|

|

B11C7:46

|

High Beam Sensor: Calibration / Parameter Memory Failure

|

GO to Pinpoint Test F F

|

|

B11C7:97

|

High Beam Sensor: Component or System Operation Obstructed or Blocked

|

GO to Pinpoint Test F F

|

|

All other

Diagnostic Trouble Codes (DTCs)

|

-

|

REFER to:

Rear View Mirrors

(501-09 Rear View Mirrors, Diagnosis and Testing).

|

Symptom Chart(s)

Symptom Chart: Headlamps

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices.

REFER to:

Diagnostic Methods

(100-00 General Information, Description and Operation).

Symptom Chart

|

Condition

|

Possible Sources

|

Actions

|

|

A module does not respond to the scan tool

|

-

Fuse

-

Wiring, terminals or connectors

-

Module

|

REFER to:

Communications Network

(418-00 Module Communications Network, Diagnosis and Testing).

|

|

The headlamp exit delay feature is inoperative

|

|

CHECK the flash-to-pass function. If the flash-to-pass is inoperative,

GO to Pinpoint Test E E

If the flash-to-pass operates, INSTALL a new

.

REFER to:

Body Control Module (BCM)

(419-10 Multifunction Electronic Modules, Removal and Installation).

|

|

One or both low beams is inoperative

|

Refer to the Pinpoint Test

|

GO to Pinpoint Test A A

|

|

One or both high beams is inoperative

|

Refer to the Pinpoint Test

|

GO to Pinpoint Test B B

|

|

One or both low beams are on continuously

|

Refer to the Pinpoint Test

|

GO to Pinpoint Test C C

|

|

One or both high beams are on continuously

|

Refer to the Pinpoint Test

|

GO to Pinpoint Test D D

|

|

The flash-to-pass feature is inoperative

|

Refer to the Pinpoint Test

|

GO to Pinpoint Test E E

|

|

The automatic high beam feature is inoperative

|

Refer to the Pinpoint Test

|

GO to Pinpoint Test F F

|

|

The adaptive front lighting is inoperative/does not operate correctly

|

Refer to the Pinpoint Test

|

GO to Pinpoint Test G G

|

Pinpoint Tests

One Or Both Low Beams is Inoperative

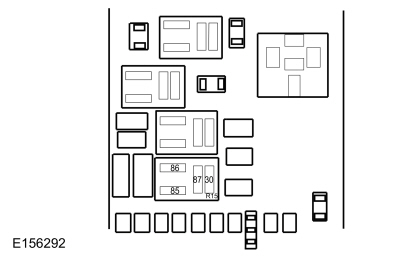

Refer to Wiring Diagrams Cell 85 for schematic and connector information.

Normal Operation and Fault Conditions

REFER to:

Exterior Lighting - System Operation and Component Description

(417-01 Exterior Lighting, Description and Operation).

Fault Trigger Conditions

|

DTC

|

Description

|

Fault Trigger Conditions

|

|

B1D00:11

|

Left Low Beam: Circuit Short To Ground

|

Sets when the

detects a short to ground from the left low beam output circuit.

|

|

B1D00:15

|

Left Low Beam: Circuit Short To Battery Or Open

|

Sets when the

detects an open from the left low beam output circuit.

|

|

B1D01:11

|

Right Low Beam: Circuit Short To Ground

|

Sets when the

detects a short to ground from the right low beam output circuit.

|

|

B1D01:15

|

Right Low Beam: Circuit Short To Battery Or Open

|

Sets when the

detects an open from the right low beam output circuit.

|

Possible Sources

-

Wiring, terminals or connectors

-

Headlamp assembly

-

Visual Inspection and Diagnostic Pre-checks

-

Inspect the headlamp assembly for damage.

-

Verify

fuses 20 (10A), 62 (50A) and 67 (50A) are OK

PINPOINT TEST A A : ONE OR BOTH LOW BEAMS IS INOPERATIVE

| A1 A1

DETERMINE IF ONE OR BOTH LOW BEAMS ARE INOPERATIVE

|

-

Place the headlamp switch in the HEADLAMPS ON position.

Are both low beams inoperative?

| Yes

|

VERIFY the

fuse 20 (10A) is OK. If OK, GO to

A9 A9

If not OK, REFER to the Wiring Diagrams manual to identify the possible causes of the circuit short.

|

| No

|

If the corresponding parking and turn lamp are also inoperative, VERIFY the

fuse 62 (50A) and 67 (50A) are OK. If OK, GO to

A2 A2

If not OK, REFER to the Wiring Diagrams manual to identify the possible causes of the circuit short.

If only the low beams are inoperative, GO to

A3 A3

|

|

| A2 A2

CHECK THE BCM (BODY CONTROL MODULE)

VOLTAGE SUPPLY CIRCUIT FOR AN OPEN

|

-

Place the headlamp switch in the OFF position.

-

Measure:

Headlamp

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C2280B-22

|

|

C1035A-57

|

Headlamp

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C2280B-21

|

|

C1035A-6

|

Is the resistance less than 3 ohms?

|

| A3 A3

CHECK FOR VOLTAGE TO THE HEADLAMP

|

-

Place the headlamp switch in the OFF position.

-

Disconnect: Inoperative

Headlamp C1509A or

Headlamp C1510A.

-

Measure:

Headlamp

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C1509A-4

|

|

Ground

|

Headlamp

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C1510A-4

|

|

Ground

|

Is the voltage greater than 11 volts?

|

| A4 A4

CHECK FOR VOLTAGE FROM THE HEADLAMP LOW BEAM CIRCUIT

|

-

Place the headlamp switch in the headlamps ON position.

-

Measure:

Headlamp

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C1509A-6

|

|

Ground

|

Headlamp

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C1510A-6

|

|

Ground

|

Is the voltage greater than 11 volts?

|

| A5 A5

CHECK THE HEADLAMP GROUND CIRCUIT FOR AN OPEN

|

-

Measure:

Headlamp

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C1509A-6

|

|

C1509A-16

|

Headlamp

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C1510A-6

|

|

C1510A-16

|

Is the voltage greater than 11 volts?

| Yes

|

INSTALL a new headlamp assembly.

REFER to:

Headlamp Assembly

(417-01 Exterior Lighting, Removal and Installation).

|

|

| A6 A6

CHECK THE LOW BEAM SUPPLY CIRCUIT FOR A SHORT TO GROUND

|

-

Place the headlamp switch in the OFF position.

-

Measure:

Headlamp

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C1509A-6

|

|

Ground

|

Headlamp

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C1510A-6

|

|

Ground

|

Is the resistance greater than 10,000 ohms?

|

| A7 A7

CHECK THE LOW BEAM SUPPLY CIRCUIT FOR AN OPEN

|

-

Measure:

Headlamp

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C1509A-6

|

|

C2280B-4

|

Headlamp

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C1510A-6

|

|

C2280B-2

|

Is the resistance less than 3 ohms?

|

| A8 A8

CHECK THE INDIVIDUAL HEADLAMP SUPPLY CIRCUIT FOR AN OPEN

|

-

Disconnect: Inoperative

Headlamp C1509A or

Headlamp C1510A.

-

Measure:

Headlamp

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C1509A-4

|

|

Ground

|

Headlamp

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C1510A-4

|

|

Ground

|

Is the voltage greater than 11 volts?

|

| A9 A9

CHECK THE HEADLAMP SUPPLY CIRCUIT FOR AN OPEN

|

-

Place the headlamp switch in the OFF position.

-

Disconnect:

Headlamp C1509A.

-

Measure:

Headlamp

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C1509A-4

|

|

Ground

|

Is the voltage greater than 11 volts?

|

| A10 A10

CHECK FOR CORRECT BCM (BODY CONTROL MODULE)

OPERATION

|

-

Disconnect and inspect all

connectors.

-

Repair:

-

corrosion (install new connector or terminals – clean module pins)

-

damaged or bent pins – install new terminals/pins

-

pushed-out pins – install new pins as necessary

-

Reconnect the

connectors. Make sure they seat and latch correctly.

-

Operate the system and determine if the concern is still present.

Is the concern still present?

| Yes

|

CHECK

for any applicable Technical Service Bulletins (TSBs). If a

exists for this concern, DISCONTINUE this test and FOLLOW

instructions. If no Technical Service Bulletins (TSBs) address this concern, INSTALL a new

.

REFER to:

Body Control Module (BCM)

(419-10 Multifunction Electronic Modules, Removal and Installation).

|

| No

|

The system is operating correctly at this time. The concern may have been caused by module connections. ADDRESS the root cause

of any connector or pin issues.

|

|

One Or Both High Beams Is Inoperative

Refer to Wiring Diagrams Cell 85 for schematic and connector information.

Normal Operation and Fault Conditions

REFER to:

Exterior Lighting - System Operation and Component Description

(417-01 Exterior Lighting, Description and Operation).

Fault Trigger Conditions

|

DTC

|

Description

|

Fault Trigger Conditions

|

|

B1D02:11

|

Left High Beam Circuit: Circuit Short To Ground

|

Sets when the

detects a short to ground from the left high beam output circuit.

|

|

B1D02:15

|

Left High Beam Circuit: Circuit Short To Battery Or Open

|

Sets when the

detects an open from the left high beam output circuit.

|

|

B1D03:11

|

Right High Beam Circuit: Circuit Short To Ground

|

Sets when the

detects a short to ground from the right high beam output circuit.

|

|

B1D03:15

|

Right High Beam Circuit: Circuit Short To Battery Or Open

|

Sets when the

detects an open from the right high beam output circuit.

|

Possible Sources

-

Wiring, terminals or connectors

-

steering column multifunction switch

-

Headlamp assembly

-

-

Visual Inspection and Diagnostic Pre-checks

-

Inspect the headlamp assembly for damage.

PINPOINT TEST B B : ONE OR BOTH HIGH BEAMS IS INOPERATIVE

| B1 B1

CHECK THE LOW BEAM OPERATION

|

-

Place the headlamp switch in the headlamps ON position.

-

Place the

steering column multifunction switch in the high beam position and observe the headlamps.

-

Place the

steering column multifunction switch in the low beam position and observe the headlamps.

Do the low beams illuminate?

| Yes

|

If an individual high beam is inoperative, GO to

B3 B3

If both high beams are inoperative, GO to

B2 B2

|

|

| B2 B2

CHECK THE MULTIFUNCTION SWITCH INPUT

|

-

Using a diagnostic scan tool, view

Parameter Identifications (PIDs).

-

Monitor the

Headlight Switch Mode (HEADLAMP_SW)

while placing the

steering column multifunction switch in the FLASH-TO-PASS and HIGH BEAM positions.

Do the

values agree with the

steering column multifunction switch position?

| No

|

INSTALL a new

steering column multifunction switch.

REFER to:

Steering Column Multifunction Switch LH

(211-05 Steering Wheel and Column Electrical Components, Removal and Installation).

TEST the system for normal operation. If the concern still exists, INSTALL a new

.

REFER to:

Steering Column Control Module (SCCM)

(211-05 Steering Wheel and Column Electrical Components, Removal and Installation).

|

|

| B3 B3

CHECK FOR VOLTAGE TO THE HEADLAMP

|

-

Place the headlamp switch in the off position.

-

Disconnect: Inoperative

Headlamp C1509A or

Headlamp C1510A.

-

Place the headlamp switch in the headlamps ON position and the

steering column multifunction switch in the high beam position.

-

Measure:

Headlamp

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C1509A-2

|

|

Ground

|

Headlamp

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C1510A-2

|

|

Ground

|

Is the voltage greater than 11 volts?

|

| B4 B4

CHECK THE HIGH BEAM GROUND CIRCUIT FOR AN OPEN

|

-

Measure:

Headlamp

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C1509A-2

|

|

C1509A-9

|

Headlamp

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C1510A-2

|

|

C1510A-9

|

Is the voltage greater than 11 volts?

| Yes

|

INSTALL a new headlamp assembly.

REFER to:

Headlamp Assembly

(417-01 Exterior Lighting, Removal and Installation).

|

|

| B5 B5

CHECK THE HIGH BEAM SUPPLY CIRCUIT FOR A SHORT TO GROUND

|

-

Place the headlamp switch in the OFF position.

-

Measure:

Headlamp

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C1509A-2

|

|

Ground

|

Headlamp

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C1510A-2

|

|

Ground

|

Is the resistance greater than 10,000 ohms?

|

| B6 B6

CHECK THE HIGH BEAM SUPPLY CIRCUIT FOR AN OPEN

|

-

Measure:

Headlamp

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C1509A-2

|

|

C C2280B-11

|

Headlamp

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C1510A-2

|

|

C C2280B-6

|

Is the resistance less than 3 ohms?

|

| B7 B7

CHECK FOR CORRECT BCM (BODY CONTROL MODULE)

OPERATION

|

-

Disconnect and inspect all

connectors.

-

Repair:

-

corrosion (install new connector or terminals – clean module pins)

-

damaged or bent pins – install new terminals/pins

-

pushed-out pins – install new pins as necessary

-

Reconnect the

connectors. Make sure they seat and latch correctly.

-

Operate the system and determine if the concern is still present.

Is the concern still present?

| Yes

|

CHECK

for any applicable Technical Service Bulletins (TSBs). If a

exists for this concern, DISCONTINUE this test and FOLLOW

instructions. If no Technical Service Bulletins (TSBs) address this concern, INSTALL a new

.

REFER to:

Body Control Module (BCM)

(419-10 Multifunction Electronic Modules, Removal and Installation).

|

| No

|

The system is operating correctly at this time. The concern may have been caused by module connections. ADDRESS the root cause

of any connector or pin issues.

|

|

One Or Both Low Beams Are On Continuously

Refer to Wiring Diagrams Cell 85 for schematic and connector information.

Normal Operation and Fault Conditions

REFER to:

Exterior Lighting - System Operation and Component Description

(417-01 Exterior Lighting, Description and Operation).

Fault Trigger Conditions

|

DTC

|

Description

|

Fault Trigger Conditions

|

|

B143B:11

|

Autolamp On Input: Circuit Short to Ground

|

Sets when the

detects a short to ground on the autolamp on input circuit.

|

|

B143C:11

|

Headlamp Off Input: Circuit Short to Ground

|

Sets when the

detects a short to ground on the headlamp off input circuit.

|

|

B143D:11

|

Headlamp On Input: Circuit Short to Ground

|

Sets when the

detects a short to ground on the headlamp on input circuit.

|

|

B143E:11

|

Headlamp Switch Input: Circuit Short to Ground

|

Sets when the

detects a short to ground on the headlamp switch input circuits.

|

|

B1447:11

|

Parklamp On Switch Input: Circuit Short to Ground

|

Sets when the

detects a short to ground on the parklamps on input circuit.

|

|

B1D00:15

|

Left Low Beam: Circuit Short to Battery or Open

|

Sets when the

detects a short to voltage from the left low beam output circuit.

|

|

B1D01:15

|

Right Low Beam: Circuit Short to Battery or Open

|

Sets when the

detects a short to voltage from the right low beam output circuit.

|

Possible Sources

-

Wiring, terminals or connectors

-

Headlamp switch

-

Visual Inspection and Diagnostic Pre-checks

-

Inspect the headlamp switch for damage.

One Or Both High Beams Are On Continuously

Refer to Wiring Diagrams Cell 85 for schematic and connector information.

Normal Operation and Fault Conditions

REFER to:

Exterior Lighting - System Operation and Component Description

(417-01 Exterior Lighting, Description and Operation).

Fault Trigger Conditions

|

DTC

|

Description

|

Fault Trigger Conditions

|

|

B1D02:15

|

Left High Beam Circuit: Circuit Short To Battery Or Open

|

Sets when the

detects a short to voltage from the left high beam output circuit.

|

|

B1D03:15

|

Right High Beam Circuit: Circuit Short To Battery Or Open

|

Sets when the

detects a short to voltage from the right high beam output circuit.

|

Possible Sources

-

Wiring, terminals or connectors

-

steering column multifunction switch

-

-

Visual Inspection and Diagnostic Pre-checks

-

Inspect the

steering column multifunction switch for damage.

PINPOINT TEST D D : ONE OR BOTH HIGH BEAMS ARE ON CONTINUOUSLY

| D1 D1

CHECK HIGH BEAMS OPERATION

|

-

Place the headlamp switch in the headlamps ON position.

-

Place the

steering column multifunction switch in the low beam position and observe the headlamps.

-

Observe the operation of the

and

high beam.

Are both high beams illuminated?

|

| D2 D2

CHECK THE MULTIFUNCTION SWITCH INPUT

|

-

Using a diagnostic scan tool, view

Parameter Identifications (PIDs).

-

Monitor the

Headlight Switch Mode (HEADLAMP_SW)

while placing the

steering column multifunction switch in the FLASH-TO-PASS, HIGH BEAM and LOW BEAM positions.

Do the

values agree with the

steering column multifunction switch position?

| No

|

INSTALL a new

steering column multifunction switch.

REFER to:

Steering Column Multifunction Switch LH

(211-05 Steering Wheel and Column Electrical Components, Removal and Installation).

TEST the system for normal operation. If the concern still exists, INSTALL a new

.

REFER to:

Steering Column Control Module (SCCM)

(211-05 Steering Wheel and Column Electrical Components, Removal and Installation).

|

|

| D3 D3

CHECK HIGH BEAM VOLTAGE SUPPLY CIRCUITS FOR A SHORT TO VOLTAGE

|

-

Disconnect:

fuse 62 (50A) (

high beam).

-

Disconnect:

fuse 67 (50A) (

high beam).

Do the high beams continue to illuminate?

|

| D4 D4

CHECK FOR CORRECT BCM (BODY CONTROL MODULE)

OPERATION

|

-

Disconnect and inspect all

connectors.

-

Repair:

-

corrosion (install new connector or terminals – clean module pins)

-

damaged or bent pins – install new terminals/pins

-

pushed-out pins – install new pins as necessary

-

Reconnect the

connectors. Make sure they seat and latch correctly.

-

Operate the system and determine if the concern is still present.

Is the concern still present?

| Yes

|

CHECK

for any applicable Technical Service Bulletins (TSBs). If a

exists for this concern, DISCONTINUE this test and FOLLOW

instructions. If no Technical Service Bulletins (TSBs) address this concern, INSTALL a new

.

REFER to:

Body Control Module (BCM)

(419-10 Multifunction Electronic Modules, Removal and Installation).

|

| No

|

The system is operating correctly at this time. The concern may have been caused by module connections. ADDRESS the root cause

of any connector or pin issues.

|

|

The Flash-To-Pass Feature Is Inoperative

Normal Operation and Fault Conditions

REFER to:

Exterior Lighting - System Operation and Component Description

(417-01 Exterior Lighting, Description and Operation).

Possible Sources

-

steering column multifunction switch

-

Visual Inspection and Diagnostic Pre-checks

-

Inspect the

steering column multifunction switch for damage.

PINPOINT TEST E E : THE FLASH-TO-PASS FEATURE IS INOPERATIVE

| E1 E1

CHECK THE HIGH BEAM OPERATION

|

-

Place the headlamp switch in the headlamps ON position.

-

Activate and deactivate the high beams using the high beam function of the

steering column multifunction switch.

Do the high beams operate correctly?

|

| E2 E2

CHECK THE MULTIFUNCTION SWITCH INPUT

|

-

Using a diagnostic scan tool, view

Parameter Identifications (PIDs).

-

Monitor the

Headlight Switch Mode (HEADLAMP_SW)

while placing the

steering column multifunction switch in the FLASH-TO-PASS position.

Does the

value agree with the

steering column multifunction switch position?

| No

|

INSTALL a new

steering column multifunction switch.

REFER to:

Steering Column Multifunction Switch LH

(211-05 Steering Wheel and Column Electrical Components, Removal and Installation).

TEST the system for normal operation. If the concern still exists, INSTALL a new

.

REFER to:

Steering Column Control Module (SCCM)

(211-05 Steering Wheel and Column Electrical Components, Removal and Installation).

|

|

| E3 E3

CHECK FOR CORRECT BCM (BODY CONTROL MODULE)

OPERATION

|

-

Disconnect and inspect all

connectors.

-

Repair:

-

corrosion (install new connector or terminals – clean module pins)

-

damaged or bent pins – install new terminals/pins

-

pushed-out pins – install new pins as necessary

-

Reconnect the

connectors. Make sure they seat and latch correctly.

-

Operate the system and determine if the concern is still present.

Is the concern still present?

| Yes

|

CHECK

for any applicable Technical Service Bulletins (TSBs). If a

exists for this concern, DISCONTINUE this test and FOLLOW

instructions. If no Technical Service Bulletins (TSBs) address this concern, INSTALL a new

.

REFER to:

Body Control Module (BCM)

(419-10 Multifunction Electronic Modules, Removal and Installation).

|

| No

|

The system is operating correctly at this time. The concern may have been caused by module connections. ADDRESS the root cause

of any connector or pin issues.

|

|

The Automatic High Beam Feature Is Inoperative

Normal Operation and Fault Conditions

The

controls the automatic high beam feature when active. The

turns the high beam headlamps on when the following conditions are met:

-

The feature has been enabled using the message center

-

The autolamps feature has turned the exterior lamps on

-

The vehicle speed is greater than 51 km/h (32 mph)

-

The

determines the ambient lighting conditions are dark enough

-

The

does not detect any light source that can be interpreted as an illuminated vehicle lamp

The

turns the high beams off if any of the following occur:

-

The

detects any light source that can be interpreted as an illuminated vehicle lamp

-

The

determines the ambient lighting conditions are not dark enough

-

The vehicle speed falls below 44 km/h (27 mph)

-

The autolamps are turned off

-

The

determines the view is blocked

REFER to:

Exterior Lighting - System Operation and Component Description

(417-01 Exterior Lighting, Description and Operation).

Fault Trigger Conditions

|

DTC

|

Description

|

Fault Trigger Conditions

|

|

B11C7:46

|

High Beam Sensor: Calibration / Parameter Memory Failure

|

Sets when the

detects a software problem with the calibrations.

|

|

B11C7:97

|

High Beam Sensor: Component or System Operation Obstructed or Blocked

|

Sets when the

detects a blockage in front of the high beam sensor.

|

Possible Sources

-

Windshield debris

-

(part of the interior rear view mirror)

PINPOINT TEST F F : THE AUTOMATIC HIGH BEAM FEATURE IS INOPERATIVE

| NOTE:

In cold weather conditions (4°C [40°F] or less), the auto high beams are inhibited for 10 minutes to allow the camera windshield

defrost heater to clear the windshield in front of the auto high beam camera.

|

| F1 F1

VERIFY THE HIGH BEAM HEADLAMP OPERATION

|

-

Place the headlamp switch in the headlamps ON position.

-

Place the

steering column multifunction switch in the high beam position while observing the headlamps.

Do the high beam headlamps illuminate?

|

| F2 F2

CHECK FOR IPMA (IMAGE PROCESSING MODULE A)

DIAGNOSTIC TROUBLE CODE (DTCS)

|

-

Using a diagnostic scan tool, perform the

self-test.

Is

B11C7:97 present?

|

| F3 F3

CARRY OUT THE IPMA (IMAGE PROCESSING MODULE A)

PROGRAMMABLE MODULE INSTALLATION (PMI) AND RETEST

|

-

Clear the Diagnostic Trouble Codes (DTCs). Repeat the self-test.

Is the concern still present?

| Yes

|

INSTALL a new interior rear view mirror.

REFER to:

Interior Rear View Mirror

(501-09 Rear View Mirrors, Removal and Installation).

|

| No

|

The system is operating correctly at this time.

|

|

| F4 F4

VERIFY THAT THE AUTOMATIC HIGH BEAM SENSOR IS NOT BLOCKED

|

-

Visually verify the automatic high beam sensor is not blocked. Sources of blockage can include:

-

stickers, window decals or tags.

-

non-OEM window tinting.

Was the automatic high beam sensor blocked?

| Yes

|

If possible, REMOVE the blockage. TEST the system for normal operation. If the blockage cannot be removed, REVIEW the operation

of the automatic high beams with the customer.

|

| No

|

INSTALL a new interior rear view mirror.

REFER to:

Interior Rear View Mirror

(501-09 Rear View Mirrors, Removal and Installation).

|

|

The Adaptive Front Lighting Is Inoperative/Does Not Operate Correctly

Normal Operation and Fault Conditions

REFER to:

Exterior Lighting - System Operation and Component Description

(417-01 Exterior Lighting, Description and Operation).

Fault Trigger Conditions

|

DTC

|

Description

|

Fault Trigger Conditions

|

|

B1087:83

|

LIN Bus "A": Value of Signal Protection Calculation Incorrect

|

Sets when the Headlamp Control Module (HCM) detects a fault on the left headlamp

circuit.

|

|

B1087:86

|

LIN Bus "A": Signal Invalid

|

Sets when the Headlamp Control Module (HCM) detects a fault on the left headlamp

circuit.

|

|

B1088:83

|

LIN Bus "B": Value of Signal Protection Calculation Incorrect

|

Sets when the Headlamp Control Module (HCM) detects a fault on the right headlamp

circuit.

|

|

B1088:86

|

LIN Bus "B": Signal Invalid

|

Sets when the Headlamp Control Module (HCM) detects a fault on the right headlamp

circuit.

|

Possible Sources

-

Wiring, terminals or connectors

-

Headlamp Control Module (HCM)

PINPOINT TEST G G : THE ADAPTIVE FRONT LIGHTING IS INOPERATIVE/DOES NOT OPERATE CORRECTLY

| G1 G1

CHECK THE OPERATION OF THE AUTOLAMPS

|

-

Place the headlamp switch in the AUTOLAMPS position.

Do the autolamps operate correctly?

| No

|

REFER to:

Autolamps

(417-01 Exterior Lighting, Diagnosis and Testing).

|

|

| G2 G2

CHECK THE HEADLAMP CONTROL MODULE (HCM) DIAGNOSTIC TROUBLE CODES (DTCS)

|

-

Place the headlamp switch in the OFF position.

-

Using a diagnostic scan tool, perform the Headlamp Control Module (HCM) self-test.

Is

B1087:83, B1087:86, B1088:83 or B1088:86 retrieved?

| No

|

INSTALL a new headlamp assembly.

REFER to:

Headlamp Assembly

(417-01 Exterior Lighting, Removal and Installation).

If the condition still exists, GO to

G8 G8

|

|

| G3 G3

CHECK THE LIN (LOCAL INTERCONNECT NETWORK)

GROUND CIRCUITS

|

-

Disconnect:

Headlamp C1509A (

B1087:83 or B1087:86) or

Headlamp C1510A (

B1088:83 or B1088:86).

-

Measure:

B1087:83 or B1087:86

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C1509A-12

|

|

Ground

|

B1088:83 or B1088:86

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C1510A-12

|

|

Ground

|

Is the resistance less than 3 ohms?

|

| G4 G4

CHECK THE LIN (LOCAL INTERCONNECT NETWORK)

CIRCUITS FOR A SHORT TO VOLTAGE

|

-

Disconnect: Headlamp Control Module (HCM) C2129.

Is any voltage present?

|

| G5 G5

CHECK THE LIN (LOCAL INTERCONNECT NETWORK)

CIRCUITS FOR A SHORT TO GROUND

|

Are the resistances greater than 10,000 ohms?

|

| G6 G6

CHECK THE LIN (LOCAL INTERCONNECT NETWORK)

CIRCUITS FOR A SHORT TO THE SHIELD

|

-

Measure:

B1087:83 or B1087:86

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C2129-9

|

|

C2129-10

|

B1088:83 or B1088:86

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C2129-21

|

|

C2129-22

|

Is the resistance greater than 10,000 ohms?

|

| G7 G7

CHECK THE LIN (LOCAL INTERCONNECT NETWORK)

CIRCUITS FOR AN OPEN

|

-

Measure:

B1087:83 or B1087:86

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C2129-10

|

|

C5109A-13

|

B1088:83 or B1088:86

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C2129-21

|

|

C1510A-13

|

Is the resistance less than 3 ohms?

|

| G8 G8

CHECK FOR CORRECT HEADLAMP CONTROL MODULE (HCM) OPERATION

|

-

Disconnect and inspect the Headlamp Control Module (HCM) connector.

-

Repair:

-

corrosion (install new connector or terminals – clean module pins)

-

damaged or bent pins – install new terminals/pins

-

pushed-out pins – install new pins as necessary

-

Reconnect the Headlamp Control Module (HCM) connector. Make sure it seats and latches correctly.

-

Operate the system and determine if the concern is still present.

Is the concern still present?

| Yes

|

CHECK

for any applicable Technical Service Bulletins (TSBs). If a

exists for this concern, DISCONTINUE this test and FOLLOW

instructions. If no Technical Service Bulletins (TSBs) address this concern, INSTALL a new Headlamp Control Module (HCM).

REFER to:

Adaptive Front Lighting Module

(417-01 Exterior Lighting, Removal and Installation).

|

| No

|

The system is operating correctly at this time. The concern may have been caused by module connections. ADDRESS the root cause

of any connector or pin issues.

|

|

U0100:00

Normal Operation and Fault Conditions

Fault Trigger Conditions

|

DTC

|

Description

|

Fault Trigger Conditions

|

|

U0100:00

|

Lost Communication With ECM/PCM "A": No Sub Type Information

|

Sets in continuous memory in the Headlamp Control Module (HCM) if data messages received from the

are missing for 5 seconds or longer.

|

Possible Sources

-

Communication concern

-

Battery voltage concern

-

-

Headlamp Control Module (HCM)

PINPOINT TEST H H : U0100:00

| H1 H1

VERIFY THE SCAN TOOL COMMUNICATES WITH THE PCM (POWERTRAIN CONTROL MODULE)

|

-

Check that a vehicle session can be established using the scan tool.

Can a vehicle session be established?

|

| H2 H2

CHECK THE HEADLAMP CONTROL MODULE (HCM) CONTINUOUS MEMORY DIAGNOSTIC TROUBLE CODES (CMDTCS)

|

-

Using a diagnostic scan tool, perform the Headlamp Control Module (HCM) self-test.

-

Clear the Diagnostic Trouble Codes (DTCs).

-

Repeat the Headlamp Control Module (HCM) self-test.

Is

U0100:00 retrieved again?

| No

|

The system is operating correctly at this time. The

may have been set due to high network traffic or an intermittent fault condition.

|

|

| H3 H3

PERFORM THE PCM (POWERTRAIN CONTROL MODULE)

KOEO (KEY ON, ENGINE OFF)

/ KOER (KEY ON, ENGINE RUNNING)

SELF-TEST

|

-

Using a diagnostic scan tool, perform the

self-test.

Are any

recorded?

| Yes

|

Refer to the appropriate section in Group 303 for the procedure.

Refer to Powertrain Control/Emissions Diagnosis (PC/ED) manual.

|

|

| H4 H4

CHECK FOR DTC (DIAGNOSTIC TROUBLE CODE)

U0100:00

|

-

Using a diagnostic scan tool, clear all Diagnostic Trouble Codes (DTCs).

-

Using a diagnostic scan tool, perform the continuous memory self-test.

-

Retrieve the Continuous Memory Diagnostic Trouble Codes (CMDTCs) from all modules.

Is

U0100:00 set in the

module?

|

U0121:00

Normal Operation and Fault Conditions

Fault Trigger Conditions

|

DTC

|

Description

|

Fault Trigger Conditions

|

|

U0121:00

|

Lost Communication With Anti-Lock Brake System (ABS) Control Module: No Sub Type Information

|

Sets in continuous memory if the Headlamp Control Module (HCM) does not receive data messages from the

module through the

are missing for 5 seconds or longer.

|

Possible Sources

-

Communication concern

-

Battery voltage concern

-

module

-

Headlamp Control Module (HCM)

-

concern

PINPOINT TEST I I : U0121:00

| I1 I1

VERIFY THE CUSTOMER CONCERN

|

-

Verify there is an observable symptom present.

Is an observable symptom present?

| No

|

The system is operating normally at this time. The

may have been set due to high network traffic or an intermittent fault condition.

|

|

| I2 I2

CHECK THE COMMUNICATION NETWORK

|

-

Using a diagnostic scan tool, perform the network test.

Does the

module pass the network test?

|

| I3 I3

PERFORM THE ABS (ANTI-LOCK BRAKE SYSTEM)

MODULE SELF-TEST

|

-

Using a diagnostic scan tool, perform the

module self-test.

Are any Diagnostic Trouble Codes (DTCs) recorded?

|

| I4 I4

CHECK FOR GWM (GATEWAY MODULE A)

CONTINUOUS MEMORY DIAGNOSTIC TROUBLE CODES (CMDTCS)

|

-

Using a diagnostic scan tool, check for

Continuous Memory Diagnostic Trouble Codes (CMDTCS)

Are any Diagnostic Trouble Codes (DTCs) recorded?

|

| I5 I5

PERFORM THE IPC (INSTRUMENT PANEL CLUSTER)

SELF-TEST

|

-

Using a diagnostic scan tool, perform the

self-test.

Is

U3006:16 or

U3006:17 recorded?

|

| I6 I6

RECHECK THE HEADLAMP CONTROL MODULE (HCM) DIAGNOSTIC TROUBLE CODES (DTCS)

|

|

NOTE:

If new modules were installed prior to the

being set, the module configuration may be incorrectly set during the Programmable Module Installation (PMI), or the Programmable

Module Installation (PMI) may not have been carried out.

-

Using a diagnostic scan tool, clear the Diagnostic Trouble Codes (DTCs).

-

Repeat the Headlamp Control Module (HCM) self-test.

Is

U0121:00 still present?

| No

|

The system is operating correctly at this time. The

may have been set due to high network traffic or an intermittent fault condition.

|

|

| I7 I7

CHECK FOR DTC (DIAGNOSTIC TROUBLE CODE)

U0121:00 SET IN OTHER MODULES

|

-

Using a diagnostic scan tool, clear all Diagnostic Trouble Codes (DTCs).

-

Using a diagnostic scan tool, perform the continuous memory self-test.

-

Retrieve the Continuous Memory Diagnostic Trouble Codes (CMDTCs) from all modules.

Is

U0121:00 set in the

?

| Yes

|

INSTALL a new

module (part of the

).

REFER to:

Hydraulic Control Unit (HCU)

(206-09 Anti-Lock Brake System (ABS) and Stability Control, Removal and Installation).

|

|

U0140:00

Normal Operation and Fault Conditions

Fault Trigger Conditions

|

DTC

|

Description

|

Fault Trigger Conditions

|

|

U0140:00

|

Lost Communication With Body Control Module: No Sub Type Information

|

Sets in continuous memory in the Headlamp Control Module (HCM) if data messages received from the

are missing for 5 seconds or longer.

|

Possible Sources

-

Communication concern

-

Battery voltage concern

-

-

Headlamp Control Module (HCM)

PINPOINT TEST J J : U0140:00

| J1 J1

VERIFY THE CUSTOMER CONCERN

|

-

Verify there is an observable symptom present.

Is an observable symptom present?

| No

|

The system is operating normally at this time. The

may have been set due to high network traffic or an intermittent fault condition.

|

|

| J2 J2

CHECK THE COMMUNICATION NETWORK

|

-

Using a diagnostic scan tool, perform the network test.

Does the

pass the network test?

|

| J3 J3

PERFORM THE BCM (BODY CONTROL MODULE)

SELF-TEST

|

-

Using a diagnostic scan tool, perform the

self-test.

Are any Diagnostic Trouble Codes (DTCs) recorded?

|

| J4 J4

RECHECK THE HEADLAMP CONTROL MODULE (HCM) DIAGNOSTIC TROUBLE CODES (DTCS)

|

|

NOTE:

If new modules were installed prior to the

being set, the module configuration may be incorrectly set during the Programmable Module Installation (PMI), or the Programmable

Module Installation (PMI) may not have been carried out.

-

Using a diagnostic scan tool, clear the Diagnostic Trouble Codes (DTCs).

-

Repeat the Headlamp Control Module (HCM) self-test.

Is

U0140:00

still present?

| No

|

The system is operating correctly at this time. The

may have been set due to high network traffic or an intermittent fault condition.

|

|

| J5 J5

CHECK FOR DTC (DIAGNOSTIC TROUBLE CODE)

U0140:00 SET IN OTHER MODULES

|

-

Using a diagnostic scan tool, clear all Diagnostic Trouble Codes (DTCs).

-

Using a diagnostic scan tool, perform the continuous memory self-test.

-

Retrieve the Continuous Memory Diagnostic Trouble Codes (CMDTCs) from all modules.

Is

U0140:00 set in the

,

or

?

|

Copyright © Ford Motor Company

Run/Start Relay Socket Pin 30

Run/Start Relay Socket Pin 30