| 413-00 Instrument Panel Cluster (IPC) and Panel Illumination

|

2013 - 2014 MKZ

|

| Diagnosis and Testing

|

Procedure revision date:

07/30/2013

|

Instrument Panel Cluster (IPC) and Panel Illumination

DTC Chart: Body Control Module (BCM)

Diagnostics in this manual assume a certian skill level and knowledge of Ford-specific diagnostic practices.

REFER to:

Diagnostic Methods

(100-00 General Information, Description and Operation).

|

DTC

|

Description

|

Action

|

|

B1314:11

|

White Lighting (Reflective Controls) Illumination Output: Circuit Short To Ground

|

GO to Pinpoint Test B

|

|

B1314:15

|

White Lighting (Reflective Controls) Illumination Output: Circuit Short To Battery or Open

|

If all non-networked illumination sources are inoperative,

GO to Pinpoint Test B

If all non-networked illumination sources are always on,

GO to Pinpoint Test D

|

|

B1436:01

|

Digital Dimmer Switch Input: General Electrical Failure

|

GO to Pinpoint Test A

|

|

U1000:00

|

Solid State Driver Protection Active- Driver Disabled: No Sub Type Information

|

The

has temporarily disabled an output because an excessive current draw exists (such as a short to ground). When this

is stored in the

, the illumination output driver (for non-networked illumination sources) is disabled until the cause of the excessive current

draw has been corrected and a successful self-test has been performed. ADDRESS all other

Diagnostic Trouble Codes (DTCs) first. After the cause of the excessive current draw has been corrected, CLEAR the Diagnostic

Trouble Codes (DTCs) and PERFORM the self-test.

|

|

U3000:49

|

Control Module: Internal Electronic Failure

|

The

has permanently disabled an output because an excessive current draw exists (such as a short to ground) that has exceeded

the limits of what the

can withstand. ADDRESS all other

Diagnostic Trouble Codes (DTCs). After the cause of the excessive current draw has been corrected, INSTALL a new

.

REFER to:

Body Control Module (BCM)

(419-10 Multifunction Electronic Modules, Removal and Installation).

|

DTC Chart: Driver Door Module (DDM)

Diagnostics in this manual assume a certian skill level and knowledge of Ford-specific diagnostic practices.

REFER to:

Diagnostic Methods

(100-00 General Information, Description and Operation).

DTC Chart: Passenger Door Module (PDM)

Diagnostics in this manual assume a certian skill level and knowledge of Ford-specific diagnostic practices.

REFER to:

Diagnostic Methods

(100-00 General Information, Description and Operation).

DTC Chart: Front Controls Interface Module (FCIM)

Diagnostics in this manual assume a certian skill level and knowledge of Ford-specific diagnostic practices.

REFER to:

Diagnostic Methods

(100-00 General Information, Description and Operation).

|

DTC

|

Description

|

Action

|

|

B113C:11

|

Hazard Switch Illumination: Circuit Short To Ground

|

CLEAR the

. WAIT at least 10 seconds. REPEAT the self-test. If

B113C:11 is retrieved again, INSTALL a new

.

REFER to:

Front Controls Interface Module (FCIM)

(415-00A Information and Entertainment System - General Information - Vehicles With: Touchscreen Display, Removal and Installation).

REFER to:

Front Controls Interface Module (FCIM)

(415-00B Information and Entertainment System - General Information - Vehicles With: THX Audio System, Removal and Installation).

|

|

All other

Diagnostic Trouble Codes (DTCs)

|

-

|

REFER to:

Information and Entertainment System

(415-00A Information and Entertainment System - General Information - Vehicles With: Touchscreen Display, Diagnosis and Testing).

REFER to:

Information and Entertainment System

(415-00B Information and Entertainment System - General Information - Vehicles With: THX Audio System, Diagnosis and Testing).

|

Symptom Chart

Symptom Chart: Instrument Cluster and Panel Illumination

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices.

REFER to:

Diagnostic Methods

(100-00 General Information, Description and Operation).

|

Condition

|

Possible Sources

|

Action

|

|

A module does not respond to the diagnostic scan tool

|

-

Fuse

-

Wiring, terminals or connectors

-

Module

|

REFER to:

Communications Network

(418-00 Module Communications Network, Diagnosis and Testing).

|

|

All illumination (networked and non-networked sources) does not dim or increase brightness

|

Refer to Pinpoint Test

|

GO to Pinpoint Test A

|

|

All non-networked illumination sources are inoperative (networked illumination functions correctly)

|

Refer to Pinpoint Test

|

GO to Pinpoint Test B

|

|

All non-networked illumination sources are always on (networked illumination functions correctly)

|

Refer to Pinpoint Test

|

GO to Pinpoint Test D

|

|

All networked illumination is inoperative (non-networked illumination fuctions correctly)

|

-

Network communication concern

-

|

-

Using a diagnostic scan tool, PERFORM a network test.

-

If all modules pass the network test, INSTALL a new

.

REFER to:

Body Control Module (BCM)

(419-10 Multifunction Electronic Modules, Removal and Installation).

-

If all modules do not pass the network test,

REFER to:

Communications Network

(418-00 Module Communications Network, Diagnosis and Testing).

|

|

One or more non-networked illumination source is inoperative

|

Refer to Pinpoint Test

|

GO to Pinpoint Test C

|

|

A single non-network illuminated switch or component is always on

|

Illuminated switch or component

|

INSTALL a new illuminated switch or component.

|

|

The steering wheel switch(es) illumination is inoperative

|

Refer to Pinpoint Test

|

GO to Pinpoint Test I

|

|

The rear interior lamp switch illumination is inoperative or always on

|

-

Rear interior lamp concern

-

Front interior lamp concern

|

-

VERIFY that the rear interior lamp can be turned on and off from the front overhead console and the front overhead console

switch illumination works properly.

-

If the rear interior lamp can be turned on and off from the front overhead console and the front overhead console switch illumination

works properly, INSTALL a new rear interior lamp.

-

If the rear interior lamp cannot be turned on and off from the front overhead console or the front overhead console switch

illumination does not work properly,

REFER to:

Interior Lighting

(417-02 Interior Lighting, Diagnosis and Testing).

|

|

The

front window control switch illumination is inoperative or always on

|

Refer to Pinpoint Test

|

GO to Pinpoint Test H

|

|

The

rear window control switch illumination is inoperative or always on

|

Refer to Pinpoint Test

|

GO to Pinpoint Test G

|

|

The

front window control switch illumination is inoperative or always on

|

Refer to Pinpoint Test

|

GO to Pinpoint Test F

|

|

The

rear window control switch illumination is inoperative or always on

|

Refer to Pinpoint Test

|

GO to Pinpoint Test J

|

|

The

front door lock/memory set switch illumination is inoperative or always on

|

Refer to Pinpoint Test

|

GO to Pinpoint Test E

|

|

The

front door lock switch illumination is inoperative or always on

|

Refer to Pinpoint Test

|

GO to Pinpoint Test F

|

|

The

illumination is inoperative or does not dim

|

-

Network communication concern

-

|

-

Using a diagnostic scan tool, PERFORM a network test.

-

If the

passes the network test, INSTALL a new

.

REFER to:

Instrument Panel Cluster (IPC)

(413-01 Instrumentation, Message Center and Warning Chimes, Removal and Installation).

-

If the diagnostic scan tool responds with no communication with the

,

REFER to:

Communications Network

(418-00 Module Communications Network, Diagnosis and Testing).

|

|

The

illumination is inoperative or does not dim

|

-

Network communication concern

-

|

-

Using a diagnostic scan tool, PERFORM a network test.

-

If the

passes the network test, INSTALL a new

.

REFER to:

Front Controls Interface Module (FCIM)

(415-00A Information and Entertainment System - General Information - Vehicles With: Touchscreen Display, Removal and Installation).

REFER to:

Front Controls Interface Module (FCIM)

(415-00B Information and Entertainment System - General Information - Vehicles With: THX Audio System, Removal and Installation).

-

If the diagnostic scan tool responds with no communication with the

,

REFER to:

Communications Network

(418-00 Module Communications Network, Diagnosis and Testing).

|

|

The hazard switch/active park assist (if equipped)/grade assist (if equipped) switch assembly illumination is inoperative

or does not dim

|

-

Network communication concern

-

|

-

Using a diagnostic scan tool, PERFORM a network test.

-

If the

passes the network test, INSTALL a new

.

REFER to:

Front Controls Interface Module (FCIM)

(415-00A Information and Entertainment System - General Information - Vehicles With: Touchscreen Display, Removal and Installation).

REFER to:

Front Controls Interface Module (FCIM)

(415-00B Information and Entertainment System - General Information - Vehicles With: THX Audio System, Removal and Installation).

-

If the diagnostic scan tool responds with no communication with the

,

REFER to:

Communications Network

(418-00 Module Communications Network, Diagnosis and Testing).

|

|

The

illumination is inoperative or does not dim

|

|

-

VERIFY that the audio system can be operated from the

.

-

If the audio system responds normally to

inputs, For diagnosing and testing please refer to the on-line Workshop Manual. If you do not have an on-line subscription, go to

www.motorcraftservice.com. If the

illumination still does not function correctly after the repair, INSTALL a new

.

REFER to:

Front Display Interface Module (FDIM)

(415-00A Information and Entertainment System - General Information - Vehicles With: Touchscreen Display, Removal and Installation).

REFER to:

Front Display Interface Module (FDIM)

(415-00B Information and Entertainment System - General Information - Vehicles With: THX Audio System, Removal and Installation).

-

If the audio system does not respond normally to

inputs,

REFER to:

Information and Entertainment System

(415-00A Information and Entertainment System - General Information - Vehicles With: Touchscreen Display, Diagnosis and Testing).

REFER to:

Information and Entertainment System

(415-00B Information and Entertainment System - General Information - Vehicles With: THX Audio System, Diagnosis and Testing).

|

|

The

illumination is inoperative or does not dim

|

-

Network communication concern

-

|

-

VERIFY that the gear selector operates properly.

-

If the gear selector operates normally, INSTALL a new Gear Shift Module (GSM).

REFER to:

Gearshift Module (GSM)

(307-05A Automatic Transmission External Controls - Vehicles With: 6-Speed Automatic Transmission - 6F50, Removal and Installation).

REFER to:

Gearshift Module (GSM)

(307-05B Automatic Transmission External Controls - Vehicles With: 6-Speed Automatic Transmission - 6F35, Removal and Installation).

-

If the gear selector does not operate normally,

REFER to:

External Controls

(307-05A Automatic Transmission External Controls - Vehicles With: 6-Speed Automatic Transmission - 6F50, Diagnosis and Testing).

REFER to:

External Controls

(307-05B Automatic Transmission External Controls - Vehicles With: 6-Speed Automatic Transmission - 6F35, Diagnosis and Testing).

|

Pinpoint Test

All Illumination (Networked and Non-Networked Sources) Does Not Dim Or Increase Brightness

Refer to Wiring Diagrams Cell 71 for schematic and connector information.

Normal Operation and Fault Conditions

The dimmer switch is integral to the headlamp switch and provides a ground to the

corresponding to the switch that is pressed (dim up or dim down).

|

DTC

|

Description

|

Fault Trigger Conditions

|

|

B1436:01

|

Digital Dimmer Switch Input: General Electrical Failure

|

This

sets on-demand and in continuous memory when the

detects a short to ground on the dim up or dim down circuit.

|

Possible Sources

-

Wiring, terminals or connectors

-

Dimmer switch (part of the headlamp switch)

-

PINPOINT TEST A : ALL ILLUMINATION (NETWORKED AND NON-NETWORKED SOURCES) DOES NOT DIM OR INCREASE BRIGHTNESS

| A1

CHECK FOR RECORDED DIAGNOSTIC TROUBLE CODES (DTCS) FROM THE BCM (BODY CONTROL MODULE)

SELF-TEST

|

-

Using a diagnostic scan tool, perform the

self-test.

Is

B1436:01 present?

|

| A2

REPEAT THE BCM (BODY CONTROL MODULE)

SELF TEST WITH THE HEADLAMP SWITCH DISCONNECTED

|

-

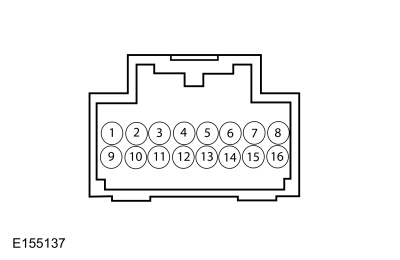

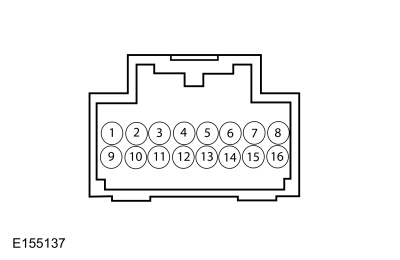

Disconnect Headlamp Switch C205

.

-

Using a diagnostic scan tool, clear the

Diagnostic Trouble Codes (DTCs).

Is

B1436:01 still present?

| No

|

INSTALL a new headlamp switch.

REFER to:

Headlamp Switch

(417-01 Exterior Lighting, Removal and Installation).

|

|

| A3

CHECK THE DIM UP AND DIM DOWN CIRCUITS FOR A SHORT TO GROUND

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C205-3

|

|

Ground

|

|

C205-6

|

|

Ground

|

Are the resistances greater than 10,000 ohms?

| No

|

REPAIR the affected circuit.

|

|

| A4

CHECK THE INSTRUMENT PANEL DIMMER SWITCH

|

-

Disconnect Headlamp Switch C205

.

-

Perform the instrument panel dimmer switch component test.

Refer to Wiring Diagrams Cell 149 for schematic and connector information.

Does the instrument panel dimmer switch pass the component test?

| No

|

INSTALL a new headlamp switch.

REFER to:

Headlamp Switch

(417-01 Exterior Lighting, Removal and Installation).

|

|

| A5

CHECK THE DIM UP AND DIM DOWN CIRCUITS FOR AN OPEN

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C205-3

|

|

C2280G-3

|

|

C205-6

|

|

C2280G-7

|

Are the resistances less than 3 ohms?

| No

|

REPAIR the affected circuit.

|

|

| A6

CHECK THE DIM UP AND DIM DOWN CIRUCITS FOR A SHORT TOGETHER

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C205-3

|

|

C205-6

|

Is the resistance greater than 10,000 ohms?

|

| A7

CHECK FOR GROUND TO THE HEADLAMP SWITCH

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C205-4

|

|

Ground

|

Is the resistance less than 3 ohms?

|

| A8

CHECK THE DIM UP AND DIM DOWN CIRCUITS FOR A SHORT TO VOLTAGE

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C205-3

|

|

Ground

|

|

C205-6

|

|

Ground

|

Is any voltage present?

| Yes

|

REPAIR the affected circuit.

|

|

| A9

CHECK FOR CORRECT BCM (BODY CONTROL MODULE)

OPERATION

|

-

Disconnect and inspect all

connectors.

-

Repair:

-

corrosion (install new connector or terminals - clean module pins)

-

damaged or bent pins - install new terminals/pins

-

pushed-out pins - install new pins as necessary

-

Reconnect the

connectors and all previously disconnected illumination system connectors. Make sure all connectors seat and latch correctly.

-

Operate the system to determine if the concern is still present.

Is the concern still present?

| Yes

|

CHECK

for any applicable Technical Service Bulletins (TSBs). If a

exists for this concern, DISCONTINUE this test and FOLLOW the

instructions. If no Technical Service Bulletins (TSBs) address this concern, INSTALL a new

.

REFER to:

Body Control Module (BCM)

(419-10 Multifunction Electronic Modules, Removal and Installation).

|

| No

|

The system is operating correctly at this time. The concern may have been caused by module connections. ADDRESS the root cause

of any connector or pin issues.

|

|

All Non-Networked Illumination Is Inoperative (Networked Illumination Functions Correctly)

Refer to Wiring Diagrams Cell 71 for schematic and connector information.

Normal Operation and Fault Conditions

REFER to:

Instrument Panel Cluster (IPC) and Panel Illumination - System Operation and Component Description

(413-00 Instrument Panel Cluster (IPC) and Panel Illumination, Description and Operation).

|

DTC

|

Description

|

Fault Trigger Conditions

|

|

B1314:11

|

White Lighting (Reflective Controls) Illumination Output: Circuit Short To Ground

|

This

sets in continuous memory and on-demand when the

detects an excessive current draw from the white lighting illumination output circuit.

|

|

B1314:15

|

White Lighting (Reflective Controls) Illumination Output: Circuit Short To Battery or Open

|

This

sets in continuous memory and on-demand when the

detects a lower than expected current draw from the white lighting illumination output circuit.

|

|

U1000:00

|

Solid State Driver Protection Active - Driver Disabled: No Sub Type Information

|

This

sets in continuous memory when the

has temporarily disabled an output driver because an excessive current draw exists (such as a short to ground). The

cannot enable the output until the cause of the excessive current draw is corrected, the

Diagnostic Trouble Codes (DTCs) have been cleared and a successful

self-test has been run.

|

|

U3000:49

|

Control Module: Internal Electronic Failure

|

This

sets in continuous memory when the

has permanently disabled an output driver because an excessive current draw (such as a short to ground) has occurred more

times than the

output driver can withstand. ADDRESS all other

Diagnostic Trouble Codes (DTCs). The cause of the excessive current draw must be corrected before a new

is installed.

|

Possible Sources

-

Wiring, terminals or connectors

-

PINPOINT TEST B : ALL NON-NETWORKED ILLUMINATION SOURCES ARE INOPERATIVE (NETWORKED ILLUMINATION FUNCTIONS CORRECTLY)

| B1

BYPASS THE BCM (BODY CONTROL MODULE)

|

-

NOTE:

If the jumper wire fuse fails during this step, refer to the Wiring Diagrams manual to identify the possible causes of the

circuit short.

Connect:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C2280G-44

|

|

CBATTERY POSITIVE

|

Do the non-networked components illuminate?

| No

|

REMOVE the fused jumper wire. REPAIR the circuit.

After the repair:

If

U1000:00 is present in the

, CLEAR the Diagnostic Trouble Codes (DTCs) and REPEAT the self-test (required to enable the illumination output driver when

U1000:00 is stored in the

).

If

U3000:49 is present in the

, INSTALL a new

after all other Diagnostic Trouble Codes (DTCs) have been addressed.

REFER to:

Body Control Module (BCM)

(419-10 Multifunction Electronic Modules, Removal and Installation).

|

|

| B2

CHECK THE BCM (BODY CONTROL MODULE)

DIAGNOSTIC TROUBLE CODES (DTCS)

|

-

Using a diagnostic scan tool, perform the

self-test.

-

Check the

Diagnostic Trouble Codes (DTCs).

Is

B1315:11 or U1000:00 currently set, or has

U1000:00 set in the past?

| Yes

|

CHECK circuit VLN37 for an intermittent short to ground. If

U1000:00 is present in the

, a successful self-test must be completed before the illumination output is enabled.

|

|

| B3

CHECK FOR CORRECT BCM (BODY CONTROL MODULE)

OPERATION

|

-

Disconnect and inspect all

connectors.

-

Repair:

-

corrosion (install new connector or terminals - clean module pins)

-

damaged or bent pins - install new terminals/pins

-

pushed-out pins - install new pins as necessary

-

Reconnect the

connectors and all previously disconnected illumination system connectors. Make sure all connectors seat and latch correctly.

-

Operate the system to determine if the concern is still present.

Is the concern still present?

| Yes

|

CHECK

for any applicable Technical Service Bulletins (TSBs). If a

exists for this concern, DISCONTINUE this test and FOLLOW the

instructions. If no Technical Service Bulletins (TSBs) address this concern, INSTALL a new

.

REFER to:

Body Control Module (BCM)

(419-10 Multifunction Electronic Modules, Removal and Installation).

|

| No

|

The system is operating correctly at this time. The concern may have been caused by module connections. ADDRESS the root cause

of any connector or pin issues.

|

|

One Or More Non-Networked Illumination Source Is Inoperative

Refer to Wiring Diagrams Cell 71 for schematic and connector information.

Normal Operation and Fault Conditions

The

supplies pulse-width modulated voltage to the non-networked illumination sources.

Possible Sources

-

Wiring, terminals or connectors

-

Illuminated component

PINPOINT TEST C : ONE OR MORE NON-NETWORKED ILLUMINATION SOURCE IS INOPERATIVE

| C1

CHECK FOR VOLTAGE TO THE INOPERATIVE COMPONENT

|

-

Disconnect inoperative illuminated component.

NOTE:

If the headlamp switch illumination is inoperative, set the instrument panel illumination to the brightest setting with the

ignition on prior to disconnecting the headlamp switch.

-

Place a shop light over the ambient light sensor to make sure the illumination can reach maximum brightness.

-

Place the headlamp switch in the PARKING LAMPS ON position.

-

Press the instrument panel dimmer switch up until the illumination reaches full brightness.

Is the voltage greater than 11 volts?

|

| C2

CHECK FOR VOLTAGE TO THE COMPONENT USING CONNECTOR GROUND

|

Is the voltage greater than 11 volts?

| Yes

|

INSTALL a new component in question.

|

| No

|

REPAIR the circuit in question.

|

|

All Non-Networked Illumination Is Always On (Networked Illumination Functions Correctly)

Refer to Wiring Diagrams Cell 71 for schematic and connector information.

Normal Operation and Fault Conditions

REFER to:

Instrument Panel Cluster (IPC) and Panel Illumination - System Operation and Component Description

(413-00 Instrument Panel Cluster (IPC) and Panel Illumination, Description and Operation).

|

DTC

|

Description

|

Fault Trigger Conditions

|

|

B1314:15

|

White Lighting (Reflective Controls) Illumination Output: Circuit Short To Battery or Open

|

This

sets in continuous memory and on-demand when the

detects a lower than expected current draw from the white lighting illumination output circuit.

|

Possible Sources

-

Wiring, terminals or connectors

-

PINPOINT TEST D : ALL NON-NETWORKED ILLUMINATION SOURCES ARE ALWAYS ON (NETWORKED ILLUMINATION FUNCTIONS CORRECTLY)

| D1

|

-

Make sure the headlamp switch is OFF.

-

Observe the exterior lighting components.

Are any exterior lighting components illuminated?

| Yes

|

REFER to:

Headlamps

(417-01 Exterior Lighting, Diagnosis and Testing).

|

|

| D2

INSPECT THE NETWORKED ILLUMINATION SOURCES

|

-

Press the dimmer switch up and down while observing the networked illumination sources such as the

and the

.

Does the illumination function correctly on the networked illuminated components?

| No

|

REFER to the Symptom Charts in this section.

|

|

| D3

CHECK THE BCM (BODY CONTROL MODULE)

ILLUMINATION OUTPUT CIRCUIT FOR A SHORT TO VOLTAGE

|

Do the non-networked components continue to illuminate?

|

| D4

CHECK FOR CORRECT BCM (BODY CONTROL MODULE)

OPERATION

|

-

Disconnect and inspect all

connectors.

-

Repair:

-

corrosion (install new connector or terminals - clean module pins)

-

damaged or bent pins - install new terminals/pins

-

pushed-out pins - install new pins as necessary

-

Reconnect the

connectors and all previously disconnected illumination system connectors. Make sure all connectors seat and latch correctly.

-

Operate the system to determine if the concern is still present.

Is the concern still present?

| Yes

|

CHECK

for any applicable Technical Service Bulletins (TSBs). If a

exists for this concern, DISCONTINUE this test and FOLLOW the

instructions. If no Technical Service Bulletins (TSBs) address this concern, INSTALL a new

.

REFER to:

Body Control Module (BCM)

(419-10 Multifunction Electronic Modules, Removal and Installation).

|

| No

|

The system is operating correctly at this time. The concern may have been caused by module connections. ADDRESS the root cause

of any connector or pin issues.

|

|

The

Front Door Lock/Memory Set Switch Illumination Is Inoperative Or Always On

Refer to Wiring Diagrams Cell 71 for schematic and connector information.

Normal Operation and Fault Conditions

Based on messages recieved from the

, the

supplies voltage to the illuminate the

front door lock/memory set switch.

|

DTC

|

Description

|

Fault Trigger Conditions

|

|

U2010:00

|

Switch Illumination: No Sub Type Information

|

This

sets on-demand and in continuous memory when the

detects a short to ground or open on the switch illumination output circuit.

|

Possible Sources

-

Wiring, terminals or connectors

-

front door lock switch

-

PINPOINT TEST E : THE LH (LEFT-HAND)

FRONT DOOR LOCK/MEMORY SET SWITCH ILLUMINATION IS INOPERATIVE OR ALWAYS ON

| E1

PERFORM A NETWORK TEST

|

-

Using a diagnostic scan tool, perform a network test.

Does the

pass the network test?

|

| E2

VERIFY THE DOOR LOCK SWITCH FUNCTINALITY

|

-

Actuate the door locks from the

front door lock switch.

Can the doors be locked and unlocked from the

front door lock switch?

| Yes

|

If the switch illumination is inoperative, GO to

E5

If the switch illumination is always on, GO to

E3

|

|

| E3

CHECK THE ILLUMINATION CIRCUIT FOR A SHORT TO VOLTAGE

|

-

Disconnect

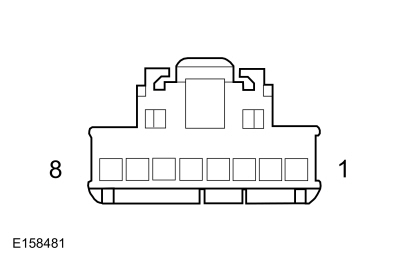

Front Door Lock Switch C541

.

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C541-2

|

|

Ground

|

Is any voltage present?

| No

|

The system is operating correctly at this time, CHECK the illumination output for an intermittent short to voltage.

|

|

| E4

CHECK THE ILLUMINATION CIRCUIT FOR A SHORT TO VOLTAGE WITH THE DDM (DRIVER DOOR MODULE)

DISCONNECTED

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C541-2

|

|

Ground

|

Is any voltage present?

|

| E5

CHECK THE ILLUMINATION CIRCUIT FOR VOLTAGE AT THE DOOR LOCK SWITCH

|

-

Disconnect

Front Door Lock Switch C541

.

-

Connect:

|

Lead 1

|

Measurement / Action

|

Lead 2

|

|

C541-2

|

|

Ground

|

-

Place a shop light over the ambient light sensor to make sure the illumination can reach maximum brightness.

-

Press the instrument panel dimmer switch up until the illumination reaches full brightness.

Does the test light illuminate?

| Yes

|

INSTALL a new

front door lock switch.

REFER to:

Door Lock Control Switch

(501-14 Handles, Locks, Latches and Entry Systems, Removal and Installation).

|

|

| E6

CHECK THE ILLUMINATION CIRCUIT FOR A SHORT TO GROUND

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C541-2

|

|

Ground

|

Is the resistance greater than 10,000 ohms?

|

| E7

CHECK THE ILLUMINATION CIRCUIT FOR AN OPEN BETWEEN THE DOOR LOCK SWITCH AND THE DDM (DRIVER DOOR MODULE)

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C541-2

|

|

C501A-15

|

Is the resistance less than 3 ohms?

|

| E8

CHECK THE DOOR LOCK SWITCH ILLUMINATION AND GROUND CIRCUITS FOR A SHORT TOGETHER

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C541-2

|

|

C541-6

|

Is the resistance greater than 10,000 ohms?

|

| E9

CHECK FOR CORRECT DDM (DRIVER DOOR MODULE)

OPERATION

|

-

Disconnect and inspect all

connectors.

-

Repair:

-

corrosion (install new connector or terminals - clean module pins)

-

damaged or bent pins - install new terminals/pins

-

pushed-out pins - install new pins as necessary

-

Reconnect the

connectors and all previously disconnected illumination system connectors. Make sure all connectors seat and latch correctly.

-

Operate the system to determine if the concern is still present.

Is the concern still present?

| Yes

|

CHECK

for any applicable Technical Service Bulletins (TSBs). If a

exists for this concern, DISCONTINUE this test and FOLLOW the

instructions. If no Technical Service Bulletins (TSBs) address this concern, INSTALL a new

.

REFER to:

Driver Door Module (DDM)

(419-10 Multifunction Electronic Modules, Removal and Installation).

|

| No

|

The system is operating correctly at this time. The concern may have been caused by module connections. ADDRESS the root cause

of any connector or pin issues.

|

|

The

Front Door Lock And/Or Window Control Switch Illumination Is Inoperative Or Always On

Refer to Wiring Diagrams Cell 71 for schematic and connector information.

Normal Operation and Fault Conditions

Based on messages recieved from the

, the

supplies voltage to the illuminate the

front door lock switch and window control switch. The

door lock and window control switch illumination shares a common power circuit.

|

DTC

|

Description

|

Fault trigger conditions

|

|

U2010:00

|

Switch Illumination: No Sub Type Information

|

This

sets on-demand and in continuous memory when the

detects a short to ground or open on the switch illumination output circuit.

|

Possible Sources

-

Wiring, terminals or connectors

-

-

door lock switch

-

window control switch

PINPOINT TEST F : THE RH (RIGHT-HAND)

FRONT DOOR LOCK AND/OR WINDOW CONTROL SWITCH ILLUMINATION IS INOPERATIVE OR ALWAYS ON

| F1

PERFORM A NETWORK TEST

|

-

Using a diagnostic scan tool, perform a network test.

Does the

pass the network test?

| Yes

|

If the door lock

and

window control switch illumination is inoperative,

GO to

F5

If the door lock control switch illumination is inoperative,

GO to

F9

If the window control switch illumination is inoperative,

GO to

F12

If the door lock

and

window control switch illumination is always on,

GO to

F2

|

|

| F2

CHECK THE ILLUMINATION CIRCUIT FOR A SHORT TO VOLTAGE

|

-

Disconnect

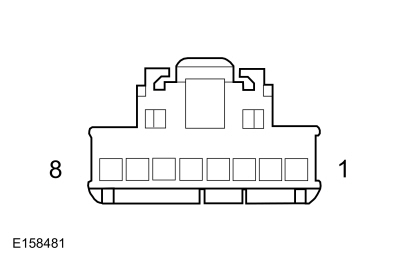

Front Window Control Switch C624

.

-

Make sure all other illuminated switches inside the vehilce have turned OFF before continuing.

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C624-4

|

|

Ground

|

Is any voltage present?

| No

|

The system is functioning correctly at this time. CHECK the illumination output circuit for an intermittent short to voltage.

|

|

| F3

CHECK THE ILLUMINATION CIRCUIT FOR A SHORT TO VOLTAGE WITH THE PDM (PASSENGER DOOR MODULE)

DISCONNECTED

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C624-4

|

|

Ground

|

Is any voltage present?

|

| F4

CHECK THE SWITCH CIRCUITS FOR A SHORT TOGETHER

|

Are the resistances greater than 10,000 ohms?

| No

|

REPAIR the affected circuit.

|

|

| F5

VERIFY THE DOOR LOCK SWITCH FUNCTIONALITY

|

-

Actuate the door locks from the

front door lock switch.

Does the

door lock switch function correctly?

|

| F6

CHECK THE ILLUMINATION CIRCUIT FOR VOLTAGE

|

-

Disconnect

Front Window Control Switch C624

.

-

Connect:

|

Lead 1

|

Measurement / Action

|

Lead 2

|

|

C624-4

|

|

Ground

|

-

Place a shop light over the ambient light sensor to make sure the illumination can reach maximum brightness.

-

Press the instrument panel dimmer switch up until the illumination reaches full brightness.

Does the test light illuminate?

| Yes

|

The system is functioning correctly at this time, CHECK the illumination output circuit for an intermitent fault condition.

|

|

| F7

CHECK THE ILLUMINATION CIRCUIT FOR AN OPEN

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C624-4

|

|

C652A-15

|

Is the resistance less than 3 ohms?

|

| F8

CHECK THE ILLUMINATION CIRCUIT FOR A SHORT TO GROUND

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C624-4

|

|

Ground

|

Is the resistance greater than 10,000 ohms?

| No

|

REPAIR the affected circuit.

|

|

| F9

VERIFY THE RH (RIGHT-HAND)

DOOR LOCK CONTROL SWITCH OPERATION

|

-

Verify the operation of the door lock from the

door lock control switch.

Does the door lock operate correctly?

|

| F10

CHECK THE ILLUMINATION CIRCUIT FOR VOLTAGE

|

-

Disconnect

Door Lock Control Switch C605

.

-

Connect:

|

Lead 1

|

Measurement / Action

|

Lead 2

|

|

C605-1

|

|

C605-3

|

-

Place a shop light over the ambient light sensor to make sure the illumination can reach maximum brightness.

-

Press the instrument panel dimmer switch up until the illumination reaches full brightness.

Does the test light illuminate?

| Yes

|

INSTALL new door lock control switch.

REFER to:

Door Lock Control Switch

(501-14 Handles, Locks, Latches and Entry Systems, Removal and Installation).

|

|

| F11

CHECK THE ILLUMINATION CIRCUIT FOR AN OPEN

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C605-1

|

|

C652A-15

|

Is the resistance less than 3 ohms?

|

| F12

CHECK THE ILLUMINATION CIRCUIT FOR VOLTAGE

|

-

Disconnect

Front Window Control Switch C624

.

-

Connect:

|

Lead 1

|

Measurement / Action

|

Lead 2

|

|

C624-4

|

|

C624-6

|

-

Place a shop light over the ambient light sensor to make sure the illumination can reach maximum brightness.

-

Press the instrument panel dimmer switch up until the illumination reaches full brightness.

Does the test light illuminate?

|

| F13

CHECK THE ILLUMINATION CIRCUIT FOR AN OPEN

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C624-4

|

|

C652A-15

|

Is the resistance less than 3 ohms?

|

| F14

CHECK THE ILLUMINATION GROUND CIRCUIT FOR AN OPEN

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C624-6

|

|

C652A-17

|

Is the resistance less than 3 ohms?

|

| F15

CHECK FOR CORRECT PDM (PASSENGER DOOR MODULE)

OPERATION

|

-

Disconnect and inspect all

connectors.

-

Repair:

-

corrosion (install new connector or terminals - clean module pins)

-

damaged or bent pins - install new terminals/pins

-

pushed-out pins - install new pins as necessary

-

Reconnect the

connectors and all previously disconnected illumination system connectors. Make sure all connectors seat and latch correctly.

-

Operate the system to determine if the concern is still present.

Is the concern still present?

| Yes

|

CHECK

for any applicable Technical Service Bulletins (TSBs). If a

exists for this concern, DISCONTINUE this test and FOLLOW the

instructions. If no Technical Service Bulletins (TSBs) address this concern, INSTALL a new

.

REFER to:

Passenger Door Module (PDM)

(419-10 Multifunction Electronic Modules, Removal and Installation).

|

| No

|

The system is operating correctly at this time. The concern may have been caused by module connections. ADDRESS the root cause

of any connector or pin issues.

|

|

The

Rear Window Control Switch Illumination Is Inoperative Or Always On

Refer to Wiring Diagrams Cell 71 for schematic and connector information.

Normal Operation and Fault Conditions

Based on messages received from the

, the

commands the Driver Rear Door Module (DRDM) to supply voltage and ground to illuminate the

rear window control switch via a

circuit.

|

DTC

|

Description

|

Fault trigger conditions

|

|

B12FF:11

|

Rear Door Switch Illumination: Circuit Short To Ground

|

This

sets on-demand and in continuous memory in the

when the Driver Rear Door Module (DRDM) detects a higher than expected current draw on the window control switch illumination

output circuit.

|

|

B12FF:15

|

Rear Door Switch Illumination: Circuit Short To Battery or Open

|

This

sets on-demand and in continuous memory in the

when the Driver Rear Door Module (DRDM) detects a lower than expected current draw on the window control switch illumination

output circuit.

|

Possible Sources

-

Wiring, terminals or connectors

-

rear window control switch

-

Driver Rear Door Module (DRDM)

PINPOINT TEST G : THE LH (LEFT-HAND)

REAR WINDOW CONTROL SWITCH ILLUMINATION IS INOPERATIVE OR ALWAYS ON

| G1

VERIFY THE POWER WINDOW FUNCTIONALITY

|

-

Operate the

rear window from the

rear window control switch

and

the

front master window control switch.

Does the

rear power window function correctly from the

rear

and

the

front master window control switch?

| Yes

|

If the

rear window control switch illumination is always on, GO to

G2

If the

rear window control switch illumination is inoperative, GO to

G4

|

|

| G2

CHECK THE ILLUMINATION OUTPUT CIRCUIT FOR A SHORT TO VOLTAGE

|

-

Disconnect

Rear Window Control Switch C701

.

-

Disconnect Driver Rear Door Module (DRDM) C728

.

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C701-4

|

|

Ground

|

Is any voltage present?

|

| G3

CHECK THE LH (LEFT-HAND)

REAR WINDOW CONTROL SWITCH CIRCUITS FOR A SHORT TOGETHER

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C701-4

|

|

C701-3

|

|

C701-4

|

|

C701-2

|

Are the resistances greater than 10,000 ohms?

| No

|

REPAIR the affected circuit.

|

|

| G4

CHECK FOR VOLTAGE TO THE ILLUMINATION OUTPUT CIRCUIT

|

-

Disconnect

Rear Window Control Switch C701

.

-

Connect:

|

Lead 1

|

Measurement / Action

|

Lead 2

|

|

C701-4

|

|

C701-6

|

-

Place a shop light over the ambient light sensor to make sure the illumination can reach maximum brightness.

-

Press the dimmer switch up until the panel illumination reaches full brightness.

Does the test light illuminate after the ignition is turned ON?

|

| G5

CHECK THE ILLUMINATION OUTPUT CIRCUIT FOR AN OPEN

|

-

Disconnect Driver Rear Door Module (DRDM) C728

.

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C701-4

|

|

C728-3

|

Is the resistance less than 3 ohms?

| No

|

REPAIR the affected circuit.

|

|

| G6

CHECK THE ILLUMINATION GROUND CIRCUIT FOR AN OPEN

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C701-6

|

|

C728-18

|

Is the resistance less than 3 ohms?

| No

|

REPAIR the affected circuit.

|

|

| G7

CHECK THE ILLUMINATION OUTPUT CIRCUIT FOR A SHORT TO GROUND

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C701-4

|

|

Ground

|

Is the resistance greater than 10,000 ohms?

| No

|

REPAIR the affected circuit.

|

|

| G8

CHECK THE ILLUMINATION CIRCUITS FOR A SHORT TOGETHER

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C701-4

|

|

C701-6

|

|

C701-4

|

|

C701-1

|

Are the resistances greater than 10,000 ohms?

| No

|

REPAIR the affected circuit.

|

|

| G9

CHECK FOR CORRECT DRIVER REAR DOOR MODULE (DRDM) OPERATION

|

-

Disconnect and inspect all Driver Rear Door Module (DRDM) connectors.

-

Repair:

-

corrosion (install new connector or terminals - clean module pins)

-

damaged or bent pins - install new terminals/pins

-

pushed-out pins - install new pins as necessary

-

Reconnect the Driver Rear Door Module (DRDM) connectors and all previously disconnected power window system connectors. Make

sure all connectors seat and latch correctly.

-

Operate the system to determine if the concern is still present.

Is the concern still present?

| Yes

|

CHECK

for any applicable Technical Service Bulletins (TSBs). If a

exists for this concern, DISCONTINUE this test and FOLLOW the

instructions. If no Technical Service Bulletins (TSBs) address this concern, INSTALL a new Driver Rear Door Module (DRDM).

REFER to:

Rear Door Module (RDM)

(419-10 Multifunction Electronic Modules, Removal and Installation).

|

| No

|

The system is operating correctly at this time. The concern may have been caused by module connections. ADDRESS the root cause

of any connector or pin issues.

|

|

The

Front Window Control Switch Illumination Is Inoperative Or Always On

Refer to Wiring Diagrams Cell 71 for schematic and connector information.

Normal Operation and Fault Conditions

Based on messages received from the

, the

commands the

front window control switch illumination level through the

circuit.

Possible Sources

-

Power window system concern

-

front window control switch

PINPOINT TEST H : THE LH (LEFT-HAND)

FRONT WINDOW CONTROL SWITCH ILLUMINATION IS INOPERATIVE OR ALWAYS ON

| H1

VERIFY THE DOOR LOCK SWITCH ILLUMINATION

|

-

Place a shop light over the ambient light sensor to make sure the illumination can reach maximum brightness.

-

Place the headlamp switch in the PARKING LAMPS ON position.

-

While pressing the instrument panel dimmer switch up and down, monitor the

front door lock control switch.

Does the

front door lock switch illumination function correctly?

|

| H2

VERIFY THE POWER WINDOW FUNCTIONALITY

|

-

Verify all of the power windows operate normally from the

front window control switch.

Do all of the windows operate normally from the

front window control switch?

|

The Steering Wheel Switch(es) Illumination Is Inoperative

Refer to Wiring Diagrams Cell 71 for schematic and connector information.

Normal Operation and Fault Conditions

The steering wheel switches receive illumination voltage from the

on the common illumination circuit through the clockspring.

Possible Sources

-

Wiring, terminals or connectors

-

Steering wheel switch(es)

-

Clockspring

-

Steering wheel

-

Driver airbag

PINPOINT TEST I : THE STEERING WHEEL SWITCH(ES) ILLUMINATION IS INOPERATIVE OR ALWAYS ON

| I1

INSPECT THE NON-NETWORKED ILLUMINATION SOURCES

|

-

Place the headlamp switch in the PARKING LAMPS ON position.

-

Place a shop light above the instrument panel ambient light sensor to make sure the

outputs maximum illumination voltage.

-

While pressing the instrument panel dimmer switch up and down, monitor the non-networked illumination sources.

Are all of the non-networked illumination source inoperative or always on?

| No

|

If

all

steering wheel switch(es) illumination is inoperative, GO to

I2

If the

and/or

upper switch(es) illumination is inoperative, GO to

I5

If the

lower switch,

lower switch,

paddle switch (downshift) or

paddle switch (upshift) illumination is inoperative, GO to

I8

|

|

| I2

CHECK FOR ILLUMINATION VOLTAGE AND GROUND AT THE CLOCKSPRING

|

-

Place the headlamp switch in the OFF position.

-

WARNING:

Turn the ignition OFF and wait one minute to deplete the backup power supply. Failure to follow this instruction may result

in serious personal injury or death in the event of an accidental deployment.

Wait one minute. WARNING:

Turn the ignition OFF and wait one minute to deplete the backup power supply. Failure to follow this instruction may result

in serious personal injury or death in the event of an accidental deployment.

Wait one minute.

-

Disconnect Clockspring C218A

.

-

Place the headlamp switch in the PARKING LAMPS ON position.

-

Press and hold the instrument panel dimmer switch up to the full illumination position.

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C218A-1

|

|

C218A-4

|

Is the voltage greater than 11 volts?

|

| I3

CHECK FOR ILLUMINATION VOLTAGE AT THE CLOCKSPRING

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C218A-1

|

|

Ground

|

Is the voltage greater than 11 volts?

| Yes

|

REPAIR the illumination ground circuit GD214 (BK/BU).

|

| No

|

REPAIR the illumination circuit VLN37 (BU/WH).

|

|

| I4

CHECK FOR ILLUMINATION VOLTAGE AND GROUND TO THE STEERING WHEEL SWITCHES

|

-

Place the headlamp switch in the OFF position.

-

Remove the driver airbag.

REFER to:

Driver Airbag

(501-20B Supplemental Restraint System, Removal and Installation).

-

Disconnect steering wheel to airbag inline.

-

Disconnect Clockspring C218B

.

-

Place the headlamp switch in the PARKING LAMPS ON position.

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

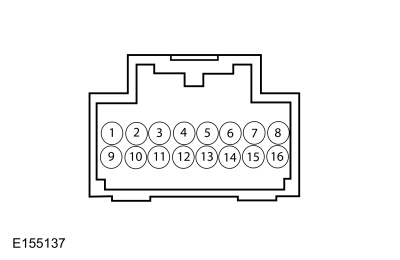

C218B-11 Component side

C218B-11 Component side

|

|

C218B-1 Component side

C218B-1 Component side

|

Is the voltage greater than 11 volts?

| Yes

|

INSTALL a new steering wheel.

REFER to:

Steering Wheel

(211-04 Steering Column, Removal and Installation).

|

| No

|

INSTALL a new clockspring.

REFER to:

Clockspring

(501-20B Supplemental Restraint System, Removal and Installation).

|

|

| I5

CHECK FOR ILLUMINATION VOLTAGE AND GROUND TO THE AIRBAG HARNESS

|

-

Place the headlamp switch in the OFF position.

-

Remove the driver airbag.

REFER to:

Driver Airbag

(501-20B Supplemental Restraint System, Removal and Installation).

-

Disconnect steering wheel to airbag inline.

-

Place the headlamp switch in the PARKING LAMPS ON position.

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

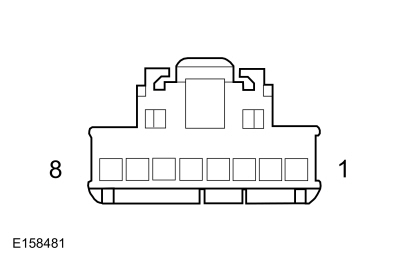

Steering Wheel to Airbag Inline - Pin 5 (Female side)

Steering Wheel to Airbag Inline - Pin 5 (Female side)

|

|

Steering Wheel to Airbag Inline - Pin 6 (Female side)

Steering Wheel to Airbag Inline - Pin 6 (Female side)

|

Is the voltage greater than 11 volts?

| Yes

|

For the

upper switch, GO to

I6

For the

upper switch, GO to

I7

|

| No

|

INSTALL a new steering wheel.

REFER to:

Steering Wheel

(211-04 Steering Column, Removal and Installation).

|

|

| I6

CHECK THE LH (LEFT-HAND)

UPPER STEERING WHEEL SWITCH

|

-

Place the headlamp switch in the OFF position.

-

Connect steering wheel to airbag inline.

-

Disconnect

Upper Steering Wheel Switch C2998

.

-

Place the headlamp switch in the PARKING LAMPS ON position.

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C2998-4

|

|

C2998-1

|

Is the voltage greater than 11 volts?

| No

|

INSTALL a new driver airbag.

REFER to:

Driver Airbag

(501-20B Supplemental Restraint System, Removal and Installation).

|

|

| I7

CHECK THE RH (RIGHT-HAND)

UPPER STEERING WHEEL SWITCH

|

-

Place the headlamp switch in the OFF position.

-

Connect steering wheel to airbag inline.

-

Disconnect

Upper Steering Wheel Switch C2999

.

-

Place the headlamp switch in the PARKING LAMPS ON position.

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C2999-4

|

|

C2999-1

|

Is the voltage greater than 11 volts?

| No

|

INSTALL a new driver airbag.

REFER to:

Driver Airbag

(501-20B Supplemental Restraint System, Removal and Installation).

|

|

| I8

CHECK THE SUSPECT STEERING WHEEL SWITCH FOR ILLUMINATION VOLTAGE AND GROUND

|

-

Place the headlamp switch in the OFF position.

-

Remove the driver airbag.

REFER to:

Driver Airbag

(501-20B Supplemental Restraint System, Removal and Installation).

-

Disconnect suspect steering wheel switch.

-

Place the headlamp switch in the PARKING LAMPS ON position.

-

Measure the voltage and ground at the inoperative steering wheel switch, harness side as follows:

lower steering wheel switch

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C2366-6

|

|

C2366-1

|

lower steering wheel switch

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C2367-6

|

|

C2367-1

|

downshift paddle switch [if equipped]

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C2429-1

|

|

C2429-2

|

upshift paddle switch [if equipped]

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C2428-4

|

|

C2428-3

|

Is the voltage greater than 11 volts?

| Yes

|

INSTALL a new steering wheel switch in question.

REFER to:

Steering Wheel Multifunction Switch

(211-05 Steering Wheel and Column Electrical Components, Removal and Installation).

REFER to:

Downshift Paddle Switch

(307-05A Automatic Transmission External Controls - Vehicles With: 6-Speed Automatic Transmission - 6F50, Removal and Installation).

REFER to:

Downshift Paddle Switch

(307-05B Automatic Transmission External Controls - Vehicles With: 6-Speed Automatic Transmission - 6F35, Removal and Installation).

REFER to:

Upshift Paddle Switch

(307-05A Automatic Transmission External Controls - Vehicles With: 6-Speed Automatic Transmission - 6F50, Removal and Installation).

REFER to:

Upshift Paddle Switch

(307-05B Automatic Transmission External Controls - Vehicles With: 6-Speed Automatic Transmission - 6F35, Removal and Installation).

|

| No

|

INSTALL a new steering wheel.

REFER to:

Steering Wheel

(211-04 Steering Column, Removal and Installation).

|

|

The

Rear Window Control Switch Illumination Is Inoperative Or Always On

Refer to Wiring Diagrams Cell 71 for schematic and connector information.

Normal Operation and Fault Conditions

Based on messages received from the

, the

commands the Passenger Rear Door Module (PRDM) to supply voltage and ground to illuminate the

rear window control switch.

|

DTC

|

Description

|

Fault trigger conditions

|

|

B12FF:11

|

Rear Door Switch Illumination: Circuit Short To Ground

|

This

sets on-demand and in continuous memory in the

when the Passenger Rear Door Module (PRDM) detects a higher than expected current draw on the window control switch illumination

output circuit.

|

|

B12FF:15

|

Rear Door Switch Illumination: Circuit Short To Battery or Open

|

This

sets on-demand and in continuous memory in the

when the Passenger Rear Door Module (PRDM) detects a lower than expected current draw on the window control switch illumination

output circuit.

|

Possible Sources

-

Wiring, terminals or connectors

-

Passenger Rear Door Module (PRDM)

-

rear window control switch

PINPOINT TEST J : THE RH (RIGHT-HAND)

REAR WINDOW CONTROL SWITCH ILLUMINATION IS INOPERATIVE OR ALWAYS ON

| J1

VERIFY THE POWER WINDOW FUNCTIONALITY

|

-

Operate the

rear window from the

rear window control switch

and

the

front master window control switch.

Does the

rear power window function correctly from the

rear

and

the

front master window control switch?

| Yes

|

If the

rear window control switch illumination is always on, GO to

J2

If the

rear window control switch illumination is inoperative, GO to

J4

|

|

| J2

CHECK THE ILLUMINATION OUTPUT CIRCUIT FOR A SHORT TO VOLTAGE

|

-

Disconnect

Rear Window Control Switch C801

.

-

Disconnect Passenger Rear Door Module (PRDM) C832

.

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C801-4

|

|

Ground

|

Is any voltage present?

|

| J3

CHECK THE RH (RIGHT-HAND)

REAR WINDOW CONTROL SWITCH CIRCUITS FOR A SHORT TOGETHER

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C801-4

|

|

C801-3

|

|

C801-4

|

|

C801-2

|

Are the resistances greater than 10,000 ohms?

| No

|

REPAIR the affected circuit.

|

|

| J4

CHECK FOR VOLTAGE TO THE ILLUMINATION OUTPUT CIRCUIT

|

-

Disconnect

Rear Window Control Switch C801

.

-

Connect:

|

Lead 1

|

Measurement / Action

|

Lead 2

|

|

C801-4

|

|

C801-6

|

-

Place a shop light over the ambient light sensor to make sure the illumination can reach maximum brightness.

-

Press the dimmer switch up until the panel illumination reaches full brightness.

Does the test light illuminate after the ignition is turned ON?

|

| J5

CHECK THE ILLUMINATION OUTPUT AND GROUND CIRCUITS FOR AN OPEN

|

-

Disconnect

Rear Window Control Switch C801

.

-

Disconnect Passenger Rear Door Module (PRDM) C832

.

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C801-4

|

|

C832-3

|

|

C801-6

|

|

C832-18

|

Are the resistances less than 3 ohms?

| No

|

REPAIR the affected circuit.

|

|

| J6

CHECK THE ILLUMINATION CIRCUITS FOR A SHORT TOGETHER

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C801-4

|

|

C801-6

|

|

C801-4

|

|

C801-1

|

Are the resistances greater than 10,000 ohms?

| No

|

REPAIR the affected circuit.

|

|

| J7

CHECK THE ILLUMINATION OUTPUT CIRCUIT FOR A SHORT TO GROUND

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C801-4

|

|

Ground

|

Is the resistance greater than 10,000 ohms?

| No

|

REPAIR the affected circuit.

|

|

| J8

CHECK FOR CORRECT PASSENGER REAR DOOR MODULE (PRDM) OPERATION

|

-

Disconnect and inspect all Passenger Rear Door Module (PRDM) connectors.

-

Repair:

-

corrosion (install new connector or terminals - clean module pins)

-

damaged or bent pins - install new terminals/pins

-

pushed-out pins - install new pins as necessary

-

Reconnect the Passenger Rear Door Module (PRDM) connectors and all previously disconnected illumination system connectors.

Make sure all connectors seat and latch correctly.

-

Operate the system to determine if the concern is still present.

Is the concern still present?

| Yes

|

CHECK

for any applicable Technical Service Bulletins (TSBs). If a

exists for this concern, DISCONTINUE this test and FOLLOW the

instructions. If no Technical Service Bulletins (TSBs) address this concern, INSTALL a new Passenger Rear Door Module (PRDM).

REFER to:

Rear Door Module (RDM)

(419-10 Multifunction Electronic Modules, Removal and Installation).

|

| No

|

The system is operating correctly at this time. The concern may have been caused by module connections. ADDRESS the root cause

of any connector or pin issues.

|

|

Copyright © Ford Motor Company

WARNING:

Turn the ignition OFF and wait one minute to deplete the backup power supply. Failure to follow this instruction may result

in serious personal injury or death in the event of an accidental deployment.

Wait one minute.

WARNING:

Turn the ignition OFF and wait one minute to deplete the backup power supply. Failure to follow this instruction may result

in serious personal injury or death in the event of an accidental deployment.

Wait one minute.

C218B-11 Component side

C218B-11 Component side

Steering Wheel to Airbag Inline - Pin 5 (Female side)

Steering Wheel to Airbag Inline - Pin 5 (Female side)