| 307-01A Automatic Transmission - Vehicles With: 6-Speed Automatic Transmission - 6F50 | 2013 - 2014 MKZ |

| Removal and Installation | Procedure revision date: 07/16/2013 |

Removal

All vehicles

NOTE: If an internal problem is suspected, drain the transmission fluid through a paper filter. A small amount of metal or friction particles may be found from normal wear. If an excessive amount of metal or friction material is present, the transmission will need to be overhauled.

Torque : 9 NmFWD

AWD

All vehicles

Installation

All vehicles

NOTICE: Make sure that when installing the manual control lever, it is fully seated onto the manual control lever shaft. Damage to the manual control lever shaft will occur and the manual lever will come loose.

NOTICE: Make sure to hold the manual control lever while tightening the manual control lever nut or damage to the manual control lever and park components will occur.

Torque : 18 NmAWD

FWD

NOTE: If the transmission has been replaced or overhauled, the halfshaft seals do not need to be replaced.

Refer to: Halfshaft Seal RH - Vehicles With: FWD (307-01A Automatic Transmission - Vehicles With: 6-Speed Automatic Transmission - 6F50, Removal and Installation).NOTE: Do not fully install the shaft at this time.

Using part: 4W1W-4N206-AAll vehicles

NOTE: If the transmission has been replaced or overhauled, the halfshaft seals do not need to be replaced.

Refer to: Halfshaft Seal LH (307-01A Automatic Transmission - Vehicles With: 6-Speed Automatic Transmission - 6F50, Removal and Installation).NOTE: Do not fully install shaft at this time.

Using part: AA5P-4N206-A.NOTE: Insert shaft until circlip is fully seated. When checking if circlip is seated do not pull on CV (constant velocity) joints or damage can result.

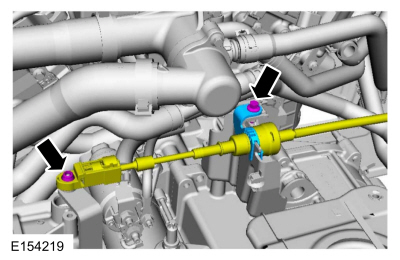

NOTE: Set the mount and roll restrictor in place and loosely install the bolt.

Material : Threadlock 262 / TA-26 (WSK-M2G351-A6)NOTE: To install the roll restrictor in the correct orientation, tighten the bolt until the roll restrictor is fixed in the mount and cannot rotate, using an open end wrench to clear the transmission fluid cooler tube.

NOTE: If a new transmisson or solenoid body is installed, the solenoid body strategy must be updated.

Refer to: Transmission Strategy Download (307-01A Automatic Transmission - Vehicles With: 6-Speed Automatic Transmission - 6F50, General Procedures).Copyright © Ford Motor Company